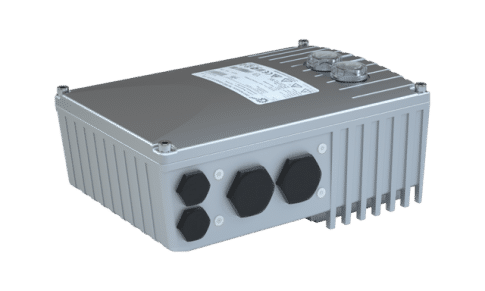

NORDAC START SK 135E motor starter

Product Details:

- Material Aluminium (Enclosure), Electronic Components (Internal)

- Processing Type Electronic Motor Starter

- Direction Forward / Reverse

- Output Torque Up to 20 Nm (Depending on Motor)

- Rated Power Up to 3.0 kW

- Input Speed 50/60 Hz (Supply Frequency)

- Output Speed Depends on Motor (Controlled By Starter)

- Click to view more

NORDAC START SK 135E motor starter Price And Quantity

- 1 , , Piece

- Integrated motor protection with phase failure monitoring

- Digital and Analog Inputs, BUS Communication (AS-Interface option)

- Powder Coated Aluminium

- Approx. 2 to 3 kg (model dependent)

- IP 55 / IP 66 (Dust and Water Protected)

- Decentralized, Direct Motor Mountable

- Integrated motor brake management

- Conveyor Systems, Pumps, Fans, Decentralized Drive Technology

- Soft Start, Reversing, Jog, and Integrated Brake Control

- -25C to +40C (standard)

NORDAC START SK 135E motor starter Product Specifications

- Depends on Motor (Controlled By Starter)

- Electronic Motor Starter

- Up to 20 Nm (Depending on Motor)

- Up to 3.0 kW

- 200-240V / 380-500V AC (50/60Hz)

- Forward / Reverse

- 50/60 Hz (Supply Frequency)

- High; Optimized Switching Efficiency

- Aluminium (Enclosure), Electronic Components (Internal)

- Integrated motor protection with phase failure monitoring

- Digital and Analog Inputs, BUS Communication (AS-Interface option)

- Powder Coated Aluminium

- Approx. 2 to 3 kg (model dependent)

- IP 55 / IP 66 (Dust and Water Protected)

- Decentralized, Direct Motor Mountable

- Integrated motor brake management

- Conveyor Systems, Pumps, Fans, Decentralized Drive Technology

- Soft Start, Reversing, Jog, and Integrated Brake Control

- -25C to +40C (standard)

NORDAC START SK 135E motor starter Trade Information

- as per order Per Week

- as per order Week

Product Description

NORDAC START SK 135E motor starter

Performance: 3 / 7.5 kW

Protection class: IP55, IP66, IP69K

Wall or motor installation

| Voltage: | 3~200-240V , 3~380-500V |

| Control terminals: | 2x DI / 2x DO |

Version:

Flexible decentralised installation outside of the control cabinet

Asynchronous motor operation

Characteristics

Control and parameterisation tools and simple parameter structure

Integrated brake rectifier for motor brake control

Integrated line filter for compliance with EMC regulations

Asynchronous motor operation

Applications:

Intralogistics

General material handling

Packaging industry

Food industry

Pump applications

Communication Interface:

AS interface

PROFIBUS DP

Robust Dust and Water Protection

Boasting IP 55 and IP 66 protection, the NORDAC START SK 135E safeguards motors against dust ingress and water jets, supporting consistent performance in challenging environments. Its powder-coated aluminium housing ensures durability even under frequent industrial cleaning or exposure to moisture.

Advanced Motor Control Functions

Designed for flexibility, the SK 135E offers soft start, reversing, jog functionalities, and integrated brake control, suitable for various dynamic applications. With precise torque management (up to 20 Nm) and direct motor mounting capability, it enables efficient and safe operation across systems.

Seamless Integration and Operational Safety

Equipped with both digital and analog inputs, and supporting BUS communication, this motor starter fits into existing control architectures easily. Integrated motor protection, phase failure monitoring, and innovative brake management maximize system uptime and safety for operators.

FAQs of NORDAC START SK 135E motor starter:

Q: How is the NORDAC START SK 135E motor starter installed for decentralized drive technology applications?

A: The SK 135E is designed for decentralized mounting, meaning it can be directly attached to the motor without the need for control panels. This simplifies installation and allows for flexible placement across conveyor systems, pumps, or fans.Q: What protection levels does the SK 135E motor starter offer against dust and water exposure?

A: The housing meets IP 55 and IP 66 protection standards, ensuring reliable performance in environments with significant dust and water exposure, making it highly suitable for industrial applications.Q: When should the integrated brake management function be used with motors?

A: The brake management feature is ideal for applications where controlled stopping and holding are required, such as conveyor systems or lifts, ensuring safe and precise motor stoppage during operation.Q: Where can the NORDAC START SK 135E be utilized within an industrial facility?

A: This motor starter is suited for use at strategic points throughout facilities, including near conveyors, pumps, and fan assemblies, thanks to its decentralized installation capability and robust construction.Q: What process does the SK 135E follow to protect motors against short circuits and phase failure?

A: The SK 135E integrates motor protection features, including short-circuit protection and phase failure monitoring, automatically disconnecting and signaling faults to prevent damage and ensure the longevity of the motor and control electronics.Q: How does BUS communication enhance the usage of the SK 135E in automated systems?

A: With optional AS-Interface BUS communication, the starter facilitates rapid data exchange between system components, allowing centralized control and monitoring for improved process efficiency and flexibility.Q: What are the most notable benefits of using the SK 135E motor starter in Indias industrial facilities?

A: The SK 135E provides high energy efficiency, robust protection, versatile control options, and is supported by local distributors and suppliers in India, making it a reliable choice for modernizing industrial drive systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+