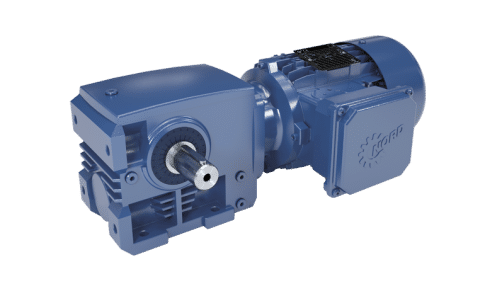

Parallel Shaft Geared Motor Parallel Shaft Gear Box

Product Details:

- Gear Type Helical (Parallel Shaft)

- Material Cast Iron, Alloy Steel

- Processing Type Precision Machined

- Gear Tooth Profile Helical

- Gearing Arrangement Parallel Shaft

- Direction Both (Reversible)

- Output Torque Up to 3500 Nm

- Click to view more

Parallel Shaft Geared Motor Parallel Shaft Gear Box Price And Quantity

- 1 Piece

- -10C to +50C

- Foot / Flange Mounted

- Robust, Shock-Resistant Design

- S1 Continuous Duty

- Natural Air Cooled

- Corrosion Resistant

- Heavy Duty Ball / Roller Bearings

- Low (< 70 dBA)

- IP55

- Oil Splash Lubrication

Parallel Shaft Geared Motor Parallel Shaft Gear Box Product Specifications

- Both (Reversible)

- Up to 50 kW

- Parallel Shaft

- Up to 3500 Nm

- Cast Iron, Alloy Steel

- Helical (Parallel Shaft)

- 1440 rpm

- 415V AC, 3 Phase, 50 Hz

- Helical

- 10 - 200 rpm

- Precision Machined

- Up to 96%

- -10C to +50C

- Foot / Flange Mounted

- Robust, Shock-Resistant Design

- S1 Continuous Duty

- Natural Air Cooled

- Corrosion Resistant

- Heavy Duty Ball / Roller Bearings

- Low (< 70 dBA)

- IP55

- Oil Splash Lubrication

Parallel Shaft Geared Motor Parallel Shaft Gear Box Trade Information

- as per order Per Week

- as per order Week

Product Description

Parallel Shaft Geared Motor Parallel Shaft Gear Box

Performance: 0.12 - 200 kW

Torque range: 110 - 100 000 Nm

Features:

| Sizes: 15 |

|

| Mounting position: M1 - M6 |

|

| Ratio: 4.03:1 6616.79:1

Versions:

|

|

In combination with central or decentralised frequency inverters, parallel shaft geared motors provide a wide range of system solutions with ultimate efficiency and economy in all systems. The UNICASE concept guarantees long life cycles and low maintenance.

Options:

Nord Parallel Shaft Geared Motor comprising of Nord Parallel Shaft Gear Box with IEC Adapter & Nord Motor

Nord Parallel Shaft Gear Box with IEC Adapter & IEC Motor

Nord Parallel Shaft Geared Motor comprising of IE2, IE3 OR IE4 Motors

Nord Parallel Shaft Gear Box with IEC Adapter

Nord Parallel Shaft Gear Box with Solid Input Shaft.

Characteristics of Nord Parallel Shaft Geared Motor:

Sleam design for space-saving installation

Robust grey cast iron housing

High efficiency for low operating costs

Various bearing concepts guarantee high axial and radial load capacities

Quiet running

Robust design for long life and easy maintenance

Cheap to run thanks to low maintenance

Application-specific versions

Applications:

Agitators

Bulk material conveyors

Cranes

Presses

Travelling drives

Versatile Mounting and Reliable Performance

With options for foot or flange mounting, this geared motor can be easily integrated into various industrial systems. Its robust design, precision machining, and corrosion-resistant paint finish guarantee consistent performance in demanding applications, offering both durability and adaptability.

Efficient Cooling and Extended Lifespan

Natural air cooling, complemented by oil splash lubrication, keeps the motors internal components operating at optimal temperatures. Heavy-duty ball and roller bearings enhance longevity while minimizing vibrations, making this geared motor suitable for continuous duty in harsh environments.

Superior Engineering and High Torque Output

Thanks to a parallel shaft helical gearing arrangement and meticulously machined alloy steel parts, the motor achieves up to 96% efficiency and delivers torque up to 3,500 Nm. This allows for reliable, reversible operation across a wide range of output speeds (10200 rpm), meeting rigorous industrial power transmission needs.

FAQs of Parallel Shaft Geared Motor Parallel Shaft Gear Box:

Q: How does the Parallel Shaft Geared Motor ensure reliable operation in industrial settings?

A: The motor utilizes precision-machined alloy steel gears in a robust cast iron housing, shock-resistant design, heavy-duty bearings, and oil splash lubrication. Its IP55 protection class and corrosion-resistant paint finish further ensure dependable operation in challenging environments.Q: What mounting options are available for installation?

A: This geared motor supports both foot and flange mounting configurations, allowing flexibility to suit a variety of machinery installations and spatial requirements in industrial facilities.Q: When should this motor be used for continuous duty cycles?

A: With an S1 continuous duty rating and natural air cooling, the motor is ideal for applications requiring uninterrupted operation, such as in manufacturing, conveyor systems, or process industries.Q: Where can this geared motor be sourced in India?

A: You can procure the Parallel Shaft Geared Motor from authorized distributors, exporters, suppliers, or traders throughout India who offer industrial power transmission equipment.Q: What is the process for maintaining the lubrication and bearings?

A: The motor features an oil splash lubrication system and heavy-duty ball or roller bearings. Regular checks of oil levels and bearing condition are recommended to sustain optimal performance and extend operational life.Q: How does reversible direction benefit industrial applications?

A: With the ability to operate in both forward and reverse directions, the motor provides versatility for applications requiring bidirectional movement, such as lifts, hoists, or conveyors.Q: What are the key benefits of using this helical parallel shaft geared motor?

A: Major advantages include high efficiency (up to 96%), low noise operation, robust shock-resistant construction, reliable torque delivery, flexible mounting, and suitability for continuous duty, making it an excellent choice for demanding industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+