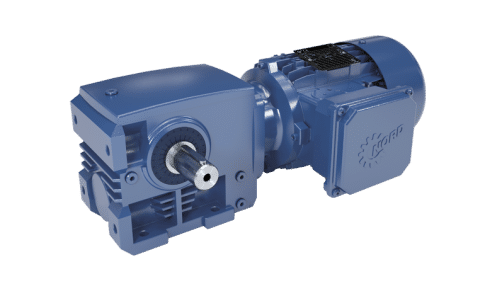

Bevel Helical Geared Motor - Bevel Helical Gear Box

Product Details:

- Gear Type Bevel Helical

- Material Cast Iron / Alloy Steel

- Processing Type Precision Machined

- Gear Tooth Profile Helical

- Gearing Arrangement Bevel Helical

- Direction Bidirectional

- Output Torque Up to 18,000 Nm

- Click to view more

Bevel Helical Geared Motor - Bevel Helical Gear Box Price And Quantity

- 1 Piece

Bevel Helical Geared Motor - Bevel Helical Gear Box Product Specifications

- Cast Iron / Alloy Steel

- Precision Machined

- Bevel Helical

- Bidirectional

- Up to 3000 rpm

- Helical

- Bevel Helical

- Up to 200 kW

- 380V / 415V

- Up to 96%

- 5 to 300 rpm

- Up to 18,000 Nm

Bevel Helical Geared Motor - Bevel Helical Gear Box Trade Information

- as per order Per Week

- as per order Week

Product Description

Bevel Helical Geared Motor - Bevel Helical Gear Box

Performance: 0.12 - 200 kW

Torque range: 180 - 50 000 Nm

Features:

| Sizes: 11 |

|

| Mounting position: M1 - M6 |

|

| Ratio: 8.04:1 - 13 432.68:1

Versions:

|

|

Options:

Nord Helical Bevel Geared Motor comprising of Nord Helical Bevel Gear Box with IEC Adapter & Nord Motor

Nord Helical Bevel Gear Box with IEC Adapter & IEC Motor

Nord Helical Bevel Geared Motor comprising of IE2, IE3 OR IE4 Motors

Nord Helical Bevel Gear Box with IEC Adapter

Nord Helical Bevel Gear Box with Solid input shaft.

Characteristics of Nord Bevel Helical Geared Motor:

High efficiency for low operating costs

Robust design for long life and easy maintenance

Cheap to run thanks to low maintenance

Robust grey cast iron housing

Various bearing concepts guarantee high axial and radial load capacities

Application-specific versions

Applications:

Intralogistics

Packaging technology

Material handling

Travelling drives

Theatre drive units

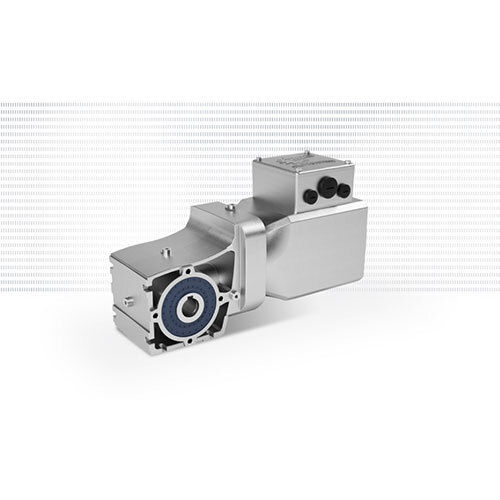

Versatile Mounting and Cooling Solutions

Choose between foot or flange mounting options to seamlessly integrate the bevel helical geared motor with your machinery. Engineered with natural air cooling, it delivers sustained, efficient performance even under demanding conditions. This flexibility enables easy installation in a wide range of industrial setups.

Exceptional Durability and Precision Engineering

Made from cast iron or alloy steel, and processed with precision machining, the housing is designed to withstand high shock loads and resist wear. The bevel helical gear configuration ensures smooth power transmission and quiet operation, maximizing productivity while reducing maintenance requirements.

Wide Application Across Industrial Sectors

Ideal for conveyors, crushers, mixers, and complex industrial machinery, this gear box addresses varied needs in sectors ranging from manufacturing and mining to material handling. Its robust construction and customizable features make it suitable for both small-scale facilities and large industrial plants.

FAQs of Bevel Helical Geared Motor - Bevel Helical Gear Box:

Q: How does the bevel helical geared motor improve efficiency in industrial machinery?

A: With a gear tooth profile designed for helical gearing and up to 96% efficiency, the bevel helical geared motor ensures smoother power transmission and reduced energy losses, maximizing output while minimizing operational costs for industrial machinery.Q: What types of mounting options are available for this gear box?

A: The gear box is available with both foot and flange mounting types, allowing easy adaptation to various machinery configurations and installation requirements.Q: When should I choose splash lubrication versus forced lubrication for this geared motor?

A: Splash lubrication is ideal for lighter-duty applications with moderate speeds, while forced lubrication is recommended in high-load or high-speed environments to ensure consistent lubrication and optimal gear life.Q: Where can this geared motor be effectively used?

A: It is suitable for a variety of settings, including conveyors, mixers, crushers, and other heavy-duty industrial machinery, making it versatile across manufacturing, mining, processing, and material handling facilities.Q: What is the process involved in manufacturing this bevel helical gear box?

A: The gear box is precision machined from cast iron or alloy steel, featuring rugged and shock-resistant housing. Advanced manufacturing techniques ensure accurate gear tooth profiles, contributing to efficient and reliable operation.Q: How does bidirectional operation benefit machinery performance?

A: Bidirectional capability allows the geared motor to run in both forward and reverse directions, providing greater flexibility and control in industrial processes that demand variable movement or direction change.Q: What are the main usage benefits of opting for a bevel helical geared motor with multiple stages?

A: Multiple stages (2, 3, or 4) enhance torque transmission, accommodate a broad range of speed and power requirements, and improve load distribution, prolonging equipment life and supporting diverse industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+