Decentralised Drive Technology

Product Details:

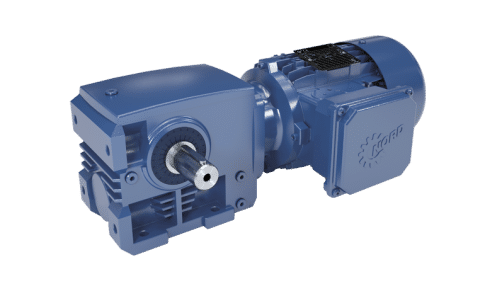

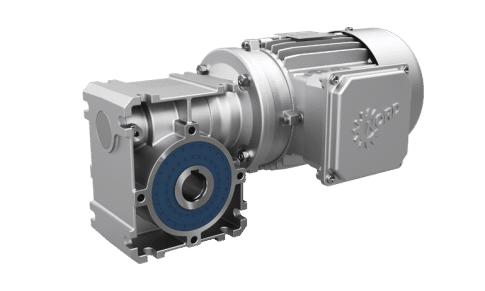

- Gear Type Helical

- Material Aluminium housing, Steel gears

- Processing Type Precision engineered

- Gear Tooth Profile Helical

- Gearing Arrangement Coaxial / Parallel shaft

- Direction Bidirectional

- Output Torque Up to 1000 Nm

- Click to view more

Decentralised Drive Technology Price And Quantity

- 1 , , Piece

Decentralised Drive Technology Product Specifications

- Up to 3000 rpm

- Bidirectional

- Up to 96%

- Helical

- Aluminium housing, Steel gears

- Up to 1000 Nm

- Up to 7.5 kW

- Coaxial / Parallel shaft

- Precision engineered

- 230V/400V AC

- Up to 300 rpm

- Helical

Decentralised Drive Technology Trade Information

- as per order Per Week

- as per order Week

Product Description

Decentralised drive technology

Performance: 0.25 - 22 kW

Protection class: IP55, IP65, IP66, IP69K

Wall, motor or field mounting

Performance: 0.55 - 7.5 kW

Protection class: IP55, IP65

Field installation

Simple installation and maintenance due to full plug-in capability

Free configuration for your application

| Voltage: | 3~380-500V |

| Control terminals: | 5 DI / 2 DO / 2 AIN (can also be used as DI) |

| Encoder interfaces: | HTL, CANopen |

Versions:

Flexible decentralised installation

Operation of synchronous and asynchronous motors

Characteristics & Advantages:

Simple installation and maintenance due to full plug-in capability as well as optional maintenance switch and local manual operation

High precision regulation with current vector control

4-quadrant operation

Integrated brake rectifier for motor brake control

PLC functionality for functions close to the drive unit (PLC on Board)

Energy-saving function for partial load operation

Control and parameterisation tools and simple parameter structure

Integrated line filter for compliance with EMC regulations

Control and closed loop regulation

POSICON - integrated positioning mode and synchronisation

STO and SS1 integrated functional safety

Integrated brake rectifier for motor brake control

Load monitor

Hoist and lifting gear functionality

Master / Slave operation

Applications:

Intralogistics

General material handling

Packaging industry

Food industry

Communication Interfaces

AS Interface

CANopen

DeviceNet

Profibus DP

EtherCAT

Ethernet/IP

Profinet

Powerlink

Superior Protection with IP65 Enclosure

Featuring an IP65 enclosure, this decentralised drive system is safeguarded against dust and water jets. This high level of protection makes it suitable for challenging industrial environments, ensuring consistent operation even in places prone to moisture and debris. The durable aluminium construction further enhances longevity, supporting applications that demand resilience and low maintenance.

Integrated Frequency Inverter for Flexible Control

The integrated frequency inverter enables precise control of speed and torque, supporting a range of input speeds up to 3000 rpm and output speeds up to 300 rpm. Its advanced electronics allow for distributed drive configurations and easy adaptation to complex material handling and conveyor systems, optimizing system performance and energy efficiency.

Efficient, Quiet, and Maintenance-Free Design

Designed for low noise operation, this drive features helical gears and coaxial or parallel shaft arrangements that minimize vibration and wear. The gears are lifetime lubricated, ensuring maintenance-free operation and reduced downtime. Compact construction and flexible mounting further contribute to seamless integration into various industrial setups.

FAQs of Decentralised Drive Technology:

Q: How does the IP65 protection class benefit industrial applications?

A: The IP65 protection class ensures the drive technology is sealed against dust and water jets, allowing it to perform reliably in challenging industrial settings such as material handling and conveyor systems, where exposure to moisture and particulates is common.Q: What mounting options are available for this decentralised drive technology?

A: This drive system offers flexible mounting, with multiple position options that enable installation on various surfaces and orientations within conveyor systems and distributed drive applications.Q: When should optional feedback systems like encoders or resolvers be considered?

A: Optional feedback systems should be utilized when precise motor control and positioning are required, such as in automated processes, synchronized material flows, or applications demanding feedback for closed-loop operation.Q: Where is this drive technology typically deployed?

A: The decentralised drive is ideal for deployment in material handling lines, automated conveyor systems, and distributed drive applications across industries such as logistics, manufacturing, and distribution centers.Q: What is the process for integrating this drive into an existing system?

A: Integration involves mounting the drive using the flexible options provided, connecting it to the power supply (230V/400V AC), and configuring the control settings via the integrated frequency inverter. Optional feedback devices can enhance control precision as needed.Q: How does lifetime lubrication reduce maintenance requirements?

A: Lifetime-lubricated gears eliminate the need for regular lubrication servicing, helping ensure uninterrupted operation and lowering overall maintenance costs, making the system virtually maintenance-free over its service life.Q: What are the main benefits of a compact and low-noise design?

A: A compact, low-noise design saves valuable space and creates a more comfortable working environment, while also reducing installation constraints. The precision helical gearing and efficient engineering contribute to smooth, quiet operation and high energy efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+