NORDAC FLEX - SK 200E frequency inverter

Product Details:

- Material High-quality industrial plastic and aluminum housing

- Processing Type Electronic variable frequency drive

- Direction Reversible (Forward/Reverse)

- Output Torque Up to 50 Nm (varies by model)

- Rated Power 0.25 kW to 22 kW

- Input Speed 05,000 rpm

- Output Speed 05,000 rpm

- Click to view more

NORDAC FLEX - SK 200E frequency inverter Price And Quantity

- 1 , , Piece

- Integrated line filter (EN 61800-3) for industrial environments

- -25C to +50C

- CE, cULus

- Multiple programmable digital and analog inputs/outputs

- 150% overload for 60 s

- V/f and Sensorless Vector Control

- Yes

- Optional parameter box with display for commissioning and diagnostics

- Integrated PROFIBUS, CANopen, EtherCAT, Ethernet/IP, and AS-Interface options

- IP55/IP66 (depending on configuration)

- Motor-mounted and wall-mounted options

- 0200 Hz output frequency

NORDAC FLEX - SK 200E frequency inverter Product Specifications

- Up to 50 Nm (varies by model)

- 05,000 rpm

- 05,000 rpm

- Reversible (Forward/Reverse)

- Electronic variable frequency drive

- Single phase 230V / Three phase 400V 10%

- High-quality industrial plastic and aluminum housing

- 0.25 kW to 22 kW

- >95% (typical)

- Integrated line filter (EN 61800-3) for industrial environments

- -25C to +50C

- CE, cULus

- Multiple programmable digital and analog inputs/outputs

- 150% overload for 60 s

- V/f and Sensorless Vector Control

- Yes

- Optional parameter box with display for commissioning and diagnostics

- Integrated PROFIBUS, CANopen, EtherCAT, Ethernet/IP, and AS-Interface options

- IP55/IP66 (depending on configuration)

- Motor-mounted and wall-mounted options

- 0200 Hz output frequency

NORDAC FLEX - SK 200E frequency inverter Trade Information

- as per order Per Week

- as per order Week

Product Description

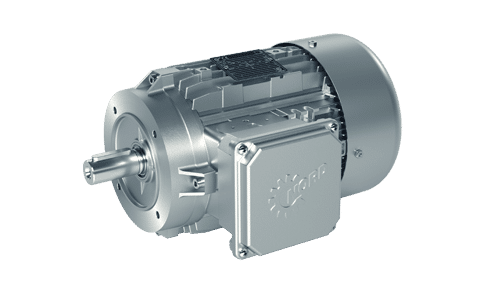

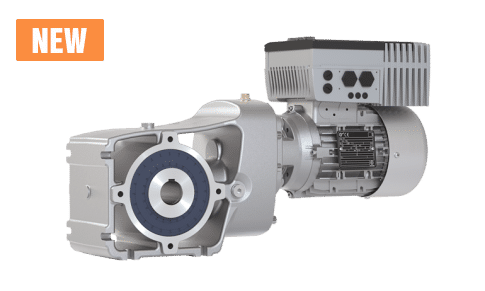

NORDAC FLEX - SK 200E frequency inverter

Performance: 0.25 - 22 kW

Protection class: IP55, IP65

Wall or motor installation

Features:

| Voltage: | 1 ~110-120V / 1/3~200-240V / 3~380-500V |

| Control terminals: | 3-4x DI (type dependent) / 1-2x DO (type dependent) / 1-2x AIN (type dependent) / 1x AOUT / Optionally extendible with TU-4 module |

| Encoder interfaces: | HTL / CANopen |

Versions:

Motor-mounted

Installation outside of the control cabinet

Characteristics:

High precision regulation with current vector control

4-quadrant operation

Integrated brake rectifier for motor brake control

PLC functionality for functions close to the drive unit (PLC on Board)

Energy-saving function for partial load operation

Control and parameterisation tools and simple parameter structure

Integrated line filter for compliance with EMC regulations

Operation of synchronous and asynchronous motors

Control and closed loop regulation

POSICON - integrated positioning mode and synchronisation

STO and SS1 integrated functional safety

Hoist and lifting gear functionality

Applications:

Intralogistics

General material handling

Packaging industry

Food industry

Pump applications

Communication Modules:

Field bus protocols

AS Interface

CANopen

DeviceNet

PROFIBUS DP

Ethernet-based bus systems

POWERLINK

EtherCAT

Ethernet/IP

PROFINET IO

Advanced Communication Features

The NORDAC FLEX - SK 200E supports seamless integration into modern automation networks with its range of built-in communication interfaces. Choose from PROFIBUS, CANopen, EtherCAT, Ethernet/IP, or AS-Interface to match your system requirements. This flexibility simplifies installation and future-proofing for distributed control environments.

Flexible Mounting Options

Offering both motor-mounted and wall-mounted configurations, the NORDAC FLEX - SK 200E adapts to a variety of installation environments. The durable housing, crafted from industrial-grade plastic and aluminum, ensures resilience and straightforward access for setup and maintenance, supporting efficient workspace management.

Integrated Safety and Efficiency

Designed for high performance, the SK 200E features an integrated line filter compliant with EN 61800-3 standards, ensuring low electromagnetic interference. With a 150% overload capacity for 60 seconds and up to 95% typical efficiency, it delivers reliable, energy-optimized operation for demanding industrial uses.

FAQs of NORDAC FLEX - SK 200E frequency inverter:

Q: How does the NORDAC FLEX - SK 200E benefit industrial automation systems?

A: This frequency inverter enhances industrial automation by providing versatile control modes, integrated communication interfaces, and robust protection, enabling efficient, reliable, and network-ready motor control suited to various manufacturing environments.Q: What mounting options are available for the SK 200E series?

A: You can install the SK 200E either directly on the motor or on the wall, allowing flexibility to adapt to space constraints or specific application requirements within your facility.Q: When should I use the integrated brake control feature?

A: Integrated brake control is particularly useful during deceleration or emergency stop situations, ensuring controlled and safe motor halting especially in conveyor, lift, or hoist applications.Q: Where is the SK 200E typically applied in industrial settings?

A: It is regularly used for controlling drives in conveyor systems, material handling, packaging machines, and various automated processes that require adjustable speed, torque, and reliable communication capabilities.Q: What is the process for commissioning and diagnosing the inverter?

A: Commissioning and diagnostics are streamlined with the optional parameter box, featuring a display that allows users to easily set parameters, monitor status, and conduct quick troubleshooting directly at the device.Q: How do the digital and analog inputs support application flexibility?

A: Multiple programmable digital and analog inputs/outputs enable tailored control setupsfacilitating functions such as start/stop commands, speed adjustments, and integration with sensors, adapting the inverter to unique process requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+