NORDAC LINK - SK 155E motor starter

Product Details:

- Material Polycarbonate (housing), coated aluminum (base plate)

- Processing Type Electronic Motor Starter

- Direction Reversible (Forward/Reverse)

- Output Torque Up to 16 Nm

- Rated Power 0.06 to 3.0 kW

- Input Speed Not Applicable (Starter Device)

- Output Speed Not Applicable (Starter Device)

- Click to view more

NORDAC LINK - SK 155E motor starter Price And Quantity

- 1 , , Piece

NORDAC LINK - SK 155E motor starter Product Specifications

- Polycarbonate (housing), coated aluminum (base plate)

- 3~ 380-500 V AC, 50/60 Hz

- Electronic Motor Starter

- Reversible (Forward/Reverse)

- Not Applicable (Starter Device)

- 0.06 to 3.0 kW

- High efficiency design

- Up to 16 Nm

- Not Applicable (Starter Device)

NORDAC LINK - SK 155E motor starter Trade Information

- as per order Per Week

- as per order Week

Product Description

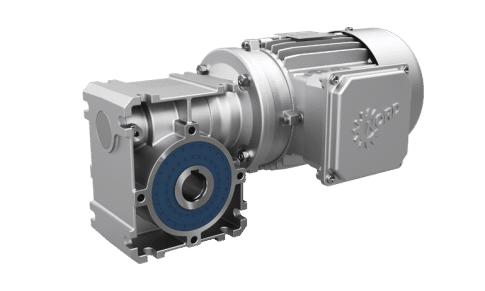

NORDAC LINK - SK 155E motor starter

Performance: - 3.00 kW

Protection class: IP65

Field installation

Simple installation and maintenance due to full plug-in capability

Free configuration for your application

| Voltage: | 3~380-500V |

| Control terminals: | 3xDI / 2xDI for evaluation via bus / 2xDO |

Versions:

Flexible decentralised installation

Asynchronous motor operation

Characteristics:

Simple installation and maintenance due to full plug-in capability as well as optional maintenance switch and local manual operation

Control and parameterisation tools and simple parameter structure

Integrated brake rectifier for motor brake control

PLC functionality for functions close to the drive unit (PLC on Board)

Reversing function

Drive unit monitoring function, including motor monitoring, motor thermistor evaluation

Optional integrated switched mains unit or external 24 V supply

Brake management for control of electro-mechanical motor brake

Integrated line filter for compliance with EMC regulations

Operation of synchronous motors

Applications:

Intralogistics

General material handling

Packaging industry

Food industry

Communication interface:

AS Interface

PROFIBUS DP

Reliable Motor Control for Demanding Environments

Designed with high IP65/IP66 protection, NORDAC LINK - SK 155E ensures robust performance in dusty and wet environments. Its decentralized mounting flexibility makes installations near the motor or on the wall straightforward, supporting efficient setup in factories, conveyors, and processing plants.

Effortless Integration with Modern Automation Networks

Offering compatibility with PROFIBUS, PROFINET, EtherNet/IP, and optional EtherCAT modules, this motor starter enables seamless communication within existing automated systems. This connectivity simplifies expansion and upgrades for operational efficiency and advanced monitoring.

Safety and Diagnostics at Your Fingertips

With optional Safe Torque Off (STO) and integrated LED status indicators, the SK 155E supports safe and reliable operations. Convenient parameterization through DIP switches and software allows easy adjustment to suit specific motor and process requirements, ensuring simplified maintenance.

FAQs of NORDAC LINK - SK 155E motor starter:

Q: How is the NORDAC LINK - SK 155E motor starter typically installed in industrial settings?

A: The motor starter is designed for decentralized mounting and can be installed directly on the wall or near the motor. Its robust IP65/IP66 protection allows placement in environments exposed to dust, moisture, or vibrations, making it suitable for various industrial applications.Q: What control interfaces are available for integrating the SK 155E into automation systems?

A: The SK 155E supports a range of control interfaces, including PROFIBUS, PROFINET, EtherNet/IP, and EtherCAT with optional communication modules. These allow for flexible integration with modern industrial networks, supporting coordinated and remote operations.Q: When should I use the direct-on-line or reversing function on this motor starter?

A: Direct-on-line starting is ideal for straightforward motor start and stop operations, while the reversing function enables changing the motors direction for processes requiring forward and reverse movement. Selection depends on your applications operational needs.Q: Where can I access diagnostic information for the SK 155E during operation?

A: Diagnostic information is displayed through integrated LED indicators on the starter itself. These LEDs provide real-time status on operation and faults, assisting with maintenance and troubleshooting clearly and efficiently.Q: What is the process for parameterizing the SK 155E motor starter?

A: Parameterization can be performed using DIP switches for fundamental settings or via connected software for advanced configuration. This flexibility allows tailored setup for different motor types and process requirements.Q: How does the integrated braking function benefit motor operation?

A: The SK 155Es integrated brake management enables controlled motor stopping and holding, which enhances operational safety and process precision, particularly in conveyor and handling systems.Q: What are the key benefits of using the NORDAC LINK - SK 155E for my industrial motor applications?

A: Benefits include high efficiency operation, advanced communication, robust safety options, easy installation, and simple diagnostics. Its durable design and flexible mounting make it an optimal choice for demanding industrial environments across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+