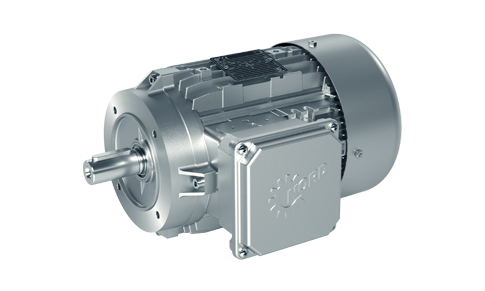

Asynchronous Motors

Product Details:

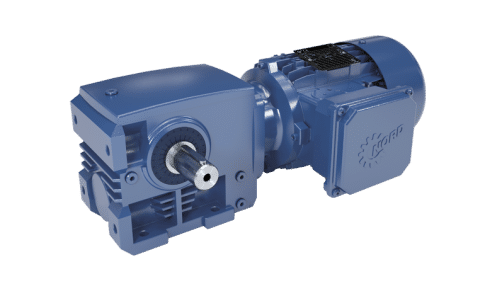

- Gear Type Helical

- Material Copper and Iron

- Processing Type Die Casting

- Gear Tooth Profile Standard Involute

- Gearing Arrangement Parallel

- Direction Bidirectional

- Output Torque 4.2 Nm

- Click to view more

X

Asynchronous Motors Price And Quantity

- 1 , , Piece

Asynchronous Motors Product Specifications

- Standard Involute

- Die Casting

- Parallel

- 4.2 Nm

- 1440 RPM

- Copper and Iron

- 1.5 kW

- 1440 RPM

- 415 V AC

- 85%

- Bidirectional

- Helical

Asynchronous Motors Trade Information

- as per order Per Week

- as per order Week

Product Description

Performance: 0.12 55 kW

Efficiency classes: IE1, IE2, IE3, IE4

Standard and smooth motors

Features:

NORD standard asynchronous motors fulfil all common efficiency regulations, are available in all international standards and are available with various options such as:

Brake (BRE), Double brake (DBR+), Incremental encoder (IG), External fan (F)

Motor protection: Temperature sensor (TF), Temperature monitor (TW), Standstill heater (SH) Motor connection: Motor plug connection (MS)

Robust Design for Diverse Industrial Use

Crafted from copper and iron using die-casting, this motor offers high reliability and robust mechanical strength. Its totally enclosed fan-cooled enclosure with IP55 protection class ensures it withstands harsh environments. The 1.5 kW power, combined with parallel helical gearing and bidirectional function, caters to various industrial applications without compromising performance or longevity.

Efficient and Safe Performance

Operating at 85% efficiency with Class F insulation and direct-on-line starting method, this motor ensures smooth and stable operation in ambient temperatures from -15C to +40C. The S1 continuous duty class and surface cooling system maintain optimal performance even during extended use, while its protective enclosure keeps the motor safe from dust and water ingress.

FAQs of Asynchronous Motors:

Q: How should the asynchronous motor be installed for optimal performance?

A: Install the motor using its foot mounting configuration on a stable, flat surface. Ensure the TEFC enclosure has ample airflow and the power supply matches the rated 415 V AC and 50 Hz. Proper alignment of the parallel helical gears ensures smooth bidirectional operation.Q: What is the primary benefit of the totally enclosed fan cooled (TEFC) enclosure accompanied by surface cooling (IC411)?

A: The TEFC design, combined with surface cooling, protects the motor from dust, moisture, and environmental contaminants. This helps to extend motor life, maintain steady operating temperature, and ensures reliable performance even in challenging environments.Q: When is it ideal to use this motor in industrial applications?

A: This motor is best suited for continuous-duty applications (S1) that require a robust drive system. Its suitable for operation in ambient temperatures ranging from -15C to +40C, making it ideal for use across a wide range of Indian industrial settings.Q: Where can these asynchronous motors be sourced, and who supplies them?

A: These motors are distributed, exported, supplied, and traded by reputable vendors and traders throughout India. They are readily available for industrial customers seeking reliable, high-efficiency three-phase motors.Q: What process is used in manufacturing the motor components?

A: Die casting is the primary processing technique used to manufacture the copper and iron components. This method ensures precise dimensional accuracy, high mechanical strength, and durability for demanding applications.Q: How does the helical gear arrangement enhance the motors operation?

A: The parallel helical gearing reduces vibration and noise during operation, providing smooth power transmission and increased reliability. The standard involute tooth profile ensures efficient torque delivery and minimal wear.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email