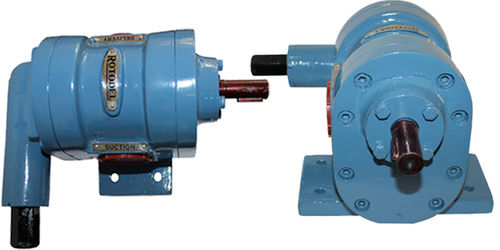

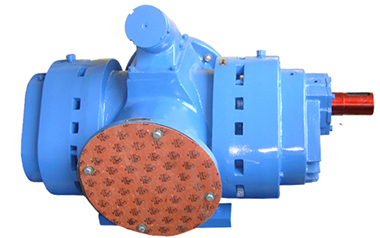

Rotary Triple Twin Gear Pump Type NDX

Product Details:

- Gear Type Internal Spur Gear

- Material Cast Iron

- Processing Type Precision-Machined

- Gear Tooth Profile Hardened Helical

- Gearing Arrangement Triple Twin Parallel

- Direction Bi-Directional

- Output Torque Up to 320 Nm

- Click to view more

Rotary Triple Twin Gear Pump Type NDX Price And Quantity

- 1 , , Piece

Rotary Triple Twin Gear Pump Type NDX Product Specifications

- Precision-Machined

- 1440 RPM

- Up to 90%

- 415 V AC

- Internal Spur Gear

- Bi-Directional

- 15 kW

- Hardened Helical

- Triple Twin Parallel

- Cast Iron

- 1440 RPM

- Up to 320 Nm

Rotary Triple Twin Gear Pump Type NDX Trade Information

- as per order Per Week

- as per order Week

Product Description

Rotary Triple Twin Gear Pump Type NDX

Uses

Rotodel NDX series pumps are designed to handle bulk volume of viscous & semi viscous liquids quite efficiently at medium pressure up to 11 bar.

The pump can be coupled directly with drive as impeller speed reduction is made possible within pump, making it very compact & cost economical & there by reducing the overall cost & space, the timing gear reduces the noise level & enhances the working life of the pump.

This pump out performance twin Screw pump in all aspect in this range & they are suitable for wagon decanting, cargo-un-loading of various viscous liquids such as edible oils, Fuel oils, viscous chemicals etc. Step-down Versions are also available; type MDX comes without reduction gears whereas type JDX comes without timing & reduction gears, type JDB is with bush bearing suitable for molasses applications.

Efficient Bi-Directional Pumping

The NDX Rotary Triple Twin Gear Pump is crafted for maximum efficiency when transferring viscous fluids in either direction. Its robust flange mounting, self-lubricated hardened helical gears, and precision-machined cast iron body ensure a consistent performance and long service life even under demanding industrial conditions.

Precision Engineering and Reliability

Each pump is engineered with internal spur gears arranged in a triple twin parallel configuration, allowing for reliable output and minimal maintenance. The use of mechanical seals and bi-directional capability adapts the pump seamlessly to varying operational needs, while maintaining up to 90% efficiency.

FAQs of Rotary Triple Twin Gear Pump Type NDX:

Q: How does the self-lubricated design of the NDX gear pump benefit industrial applications?

A: The self-lubricated feature ensures continuous smooth operation and reduces the need for maintenance even when handling viscous fluids, making it ideal for demanding industries.Q: What types of liquids can the Rotary Triple Twin Gear Pump Type NDX handle?

A: This pump is suitable for transferring a wide range of viscous liquids, such as oils and syrups, thanks to its robust materials, mechanical seal, and efficient gear design.Q: When should the NDX-3 to NDX-12 models be selected based on flow requirements?

A: Choose the appropriate model between NDX-3 to NDX-12 according to your required flow rate. These models cater to applications demanding flow rates up to 160 LPM, ensuring optimal operation without overloading the system.Q: Where is the ideal installation location for the flange-mounted NDX pump?

A: Installation is best performed in industrial environments where secure, stable mounting is possible, preferably close to the liquid source for optimal suction and minimal piping losses.Q: What process ensures the longevity of the pumps alloy steel shaft and hardened helical gears?

A: The components are precision-machined and undergo hardening treatments, resulting in exceptional durability, minimal wear, and the ability to handle up to 10 bar pressure even in harsh conditions.Q: Can this pump operate with both forward and reverse flow directions?

A: Yes, the NDX pump is designed for bi-directional operation, enabling flexible installation and reversing fluid flow as application requirements change.Q: What are the main advantages for distributors and suppliers in India working with the NDX Type pump?

A: Distributors and suppliers benefit from the pumps high efficiency, reliable performance, easy maintenance, and compatibility with standard industrial specifications, making it a versatile solution for various viscous liquid transfer needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+