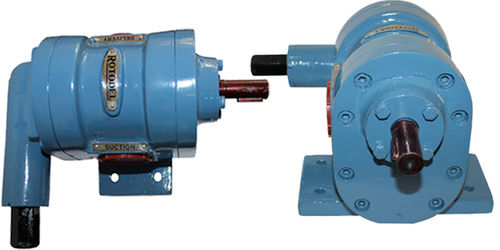

RDMNS Rotary Gear Pump

Product Details:

- Gear Type Rotary Gear

- Material Cast Iron / Stainless Steel

- Processing Type Precision Machined

- Gear Tooth Profile Spur

- Gearing Arrangement External

- Direction Clockwise and Anticlockwise

- Output Torque Up to 100 Nm

- Click to view more

RDMNS Rotary Gear Pump Price And Quantity

- 1 Piece

RDMNS Rotary Gear Pump Product Specifications

- Rotary Gear

- Up to 1440 RPM

- 0.5 HP to 10 HP

- Clockwise and Anticlockwise

- Spur

- Up to 85%

- Up to 100 Nm

- 220V/380V/415V

- Precision Machined

- Cast Iron / Stainless Steel

- Up to 1440 RPM

- External

RDMNS Rotary Gear Pump Trade Information

- as per order Per Week

- as per order Week

Product Description

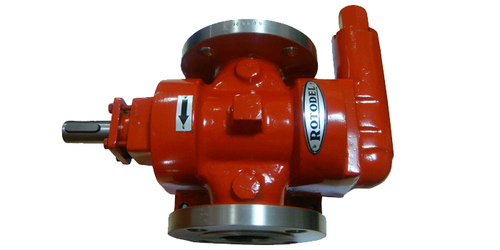

Rotary Gear Pump Type RDMNS Bitumen Gear Pump Foam Pump

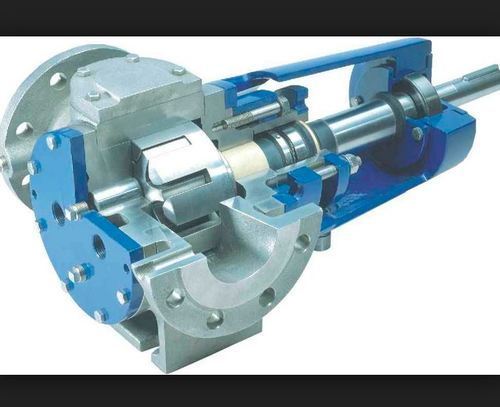

ROTODEL Rotary gear pump type RDMNS is all SS, simple four-piece construction pump specially designed to handle thinner or thicker & even corrosive liquids having lesser or no lubricating value. The SS-316 herring bone Rotors runs on Teflaon coated dry running supported on bronze wearing plate, placed inside the pump casing, alternatively graphite/bronze wearing plate cum bushes are also provided for heavier viscous liquid application. The stuffing box is fitted with Z-pack sealant with provision to fit mechanical shaft Seal. The pump is provided with add-on type pressure relief valve.

Uses

RDMNS Pumps are used for handling thinner liquid at moderate pressurizing viz. foam pressurizing application for firefighting, high pressure coolant transfer application for machine tools, light fuel pressurizing application or boiler & burners, heavy viscous liquid transfer application such as Molasses, Magma, Soap stock, Tar, Bitumen, Paints, Varnish, Crude oil etc.

MOC

Pump Body CF8

Front Cover CF8

Back Cover CF8

Gland Cover CF8

Rotar Gear SS-316

Stator Gear SS-316

Rotar Shaft EN-57/SS-430

Stator Shaft EN-57/SS-430

W.Plate - Bronze/Graphite

Bushes Teflaon Coated

Shaft Seal - Z Pack/Mech. Seal

Key SS-316

Engineered for Versatility and Durability

Built with precision, the RDMNS Rotary Gear Pump excels in diverse sectors, from oil transfer to chemical processing. Its spur gear profile and external gearing ensure consistent, smooth operation. Users benefit from both cast iron and stainless steel options, allowing the pump to handle a wide array of corrosive or viscous fluids in demanding environments.

Performance That Meets Industrial Demands

With an impressive flow rate of up to 120 LPM and pressure support up to 10 bar, this gear pump delivers power where it matters. Its reliable mechanical seal prevents leaks and the EN8 steel shaft ensures robust performance even at higher temperatures and continuous duty cycles.

FAQs of RDMNS Rotary Gear Pump:

Q: How does the RDMNS Rotary Gear Pump handle high-viscosity liquids and temperatures up to 200C?

A: The pumps external spur gear design, precision machining, and mechanical seal enable it to process viscous fluids efficiently. Its construction materials, such as cast iron or stainless steel, and an EN8 steel shaft, are chosen for their durability and high-temperature resistance, enabling operation with fluids up to 200C.Q: What is the operational process of installing and using this rotary gear pump?

A: Installation is straightforward due to its foot-mounted design. Connect the pump using appropriate-sized piping (from 1/4" to 3"), ensuring alignment for clockwise or anticlockwise rotation. Once powered with the correct voltage (220V/380V/415V), input speed can be controlled up to 1440 RPM, making the pump suitable for various industrial processes.Q: When should I choose a mechanical seal rotary gear pump over other types?

A: Mechanical seal rotary gear pumps are recommended for applications where leakage control and reliability are crucialsuch as transferring oils, chemicals, or viscous liquids at high temperatures. The mechanical seal provides better protection against leaks and contamination compared to packing-type seals.Q: Where is the RDMNS Rotary Gear Pump typically used within industrial environments?

A: This pump is ideal for industries requiring efficient transfer of oils, viscous fluids, or chemicals, such as lubricating systems, chemical plants, oil-processing units, and other fluid transfer applications. Its versatility makes it suitable for use across many sectors throughout India.Q: What benefits does the precision-machined spur gear design provide?

A: The precision-machined spur gear profile ensures smooth, reliable operation, minimizing friction and wear. This design increases the pumps efficiency up to 85%, resulting in longer service life, quieter operation, and consistent flow rates.Q: How does the gear pump accommodate different power and voltage requirements?

A: The pump is compatible with a broad power range (0.5 HP to 10 HP) and can operate at standard voltages (220V, 380V, or 415V), making it adaptable for diverse facilities and export markets with varying electrical standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+