RDBX-RDNX Type Rotary Gear Pump

Product Details:

- Gear Type Rotary Gear

- Material Cast Iron / Stainless Steel

- Processing Type Precision Machined

- Gear Tooth Profile Spur / Helical

- Gearing Arrangement External

- Direction Clockwise / Counterclockwise

- Output Torque Up to 120 Nm

- Click to view more

RDBX-RDNX Type Rotary Gear Pump Price And Quantity

- 1 Piece

RDBX-RDNX Type Rotary Gear Pump Product Specifications

- Up to 120 Nm

- Clockwise / Counterclockwise

- As per gear ratio

- Precision Machined

- Up to 85%

- Cast Iron / Stainless Steel

- Spur / Helical

- 1440 RPM

- 220V / 415V

- Rotary Gear

- Up to 15 HP

- External

RDBX-RDNX Type Rotary Gear Pump Trade Information

- as per order Per Week

- as per order Week

Product Description

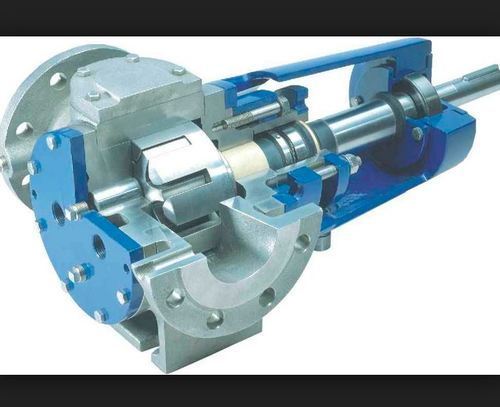

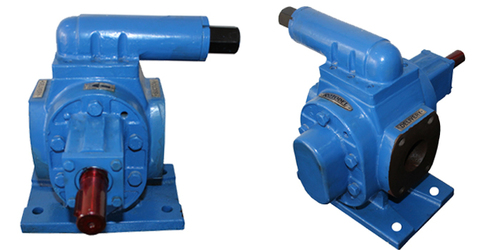

Rotary Gear Pump Type RDBX Rotary Gear Pump model RDNX Rotary Gear Pump in API versions

Handling high volume of viscous liquid at medium pressure is a challenge & calls for expertise.

The proven range of Rotodel rotary twin gear pump type 'RDRN' have been modified to achieve high pressure by reducing the bearing span, balancing the hydraulic force & blocking the slippage path but without compromising on the basic features prominent with all ROTODEL rotary pumps viz the compactness, efficiency, reliability & low noise level.

A pair of impeller with herringbone gear fitted on hardened & ground shaft with shaft sleeves in floating design supported on either side on needle/bush bearings located on end covers with ltb. wearing plate packed in between and placed inside close tolerance accurately machined casing with built in pressure relief valve makes the pump. Size 1/2" to 2 1/2" are provided with BSP thread inlet - oulet flange connections & they are available with foot or flange mounting. Size 3" to 6" are foot mounted with inlet-outlet port drilled to ASA-300 class. Type RDBX is a bush bearing version & is offered upto 2 1/2" size.

This pump can also be offered with different MOC viz. CI, CS, Bronze, SS etc. Pump upto 35 bar are also offered in this series by further reducing the bearing span. The flange type pump coupled with flange type electric motor is offered in horizontal as well as vertical construction.

Gear Pump Selection & uses

RDBX/NX series pump are medium pressure pumps designed for viscous pressure application up to 21 bar. The bush bearing version type RDBX is used for clean or dirty viscous & semi viscous liquid where the shaft surface speed is less. Pump upto 21/2" size can be run at 1440 RPM & for higher size the speed should be reduced to 960 RPM or lower. The self-lubricated needle roller bearing type can be used for clear viscous liquid & can be run at 1440 RPM for all the sizes. This pump are ideally suited for fuel pressuring, hydraulic, medium pressure lubrication & transfer applications.

All pumps are assembled after due inspection of each & every parts & than they are tested for duty parameters in accordance with API-676 & JIS-B 8312-1976.

Precision Performance and Versatile Design

This rotary gear pump offers exceptional handling of high-viscosity fluids, thanks to its external gearing arrangement and choice between spur or helical gear profiles. The mechanically sealed or gland-packed construction ensures leak-free operation even at demanding pressures and temperatures, making it a preferred choice for various oil and fuel transfer tasks.

Durable Construction for Demanding Applications

Manufactured with cast iron or stainless steel components, and finished in powder-coated or painted options, the pump provides resistance against corrosion and wear, suitable for rigorous operations. The horizontal foot-mounted setup simplifies installation, while the precision machining ensures consistent efficiency up to 85%.

FAQs of RDBX-RDNX Type Rotary Gear Pump:

Q: How does the RDBX-RDNX type rotary gear pump handle high-viscosity fluids?

A: The pump is engineered for fluids with viscosity up to 100,000 SSU, using spur or helical gears for smooth fluid transfer and minimal pulsation, making it suitable for thick oils and other viscous liquids.Q: What maintenance is required for the mechanical seal or gland packing?

A: Routine inspection for wear and leakage is advised. Mechanical seals generally require less frequent maintenance compared to gland packing, which may need tightening or replacement more regularly to prevent leaks.Q: When is it advisable to use stainless steel material for this pump?

A: Stainless steel is recommended when pumping corrosive or aggressive fluids, or when operating in environments where hygiene and rust resistance are critical, such as food processing or chemical industries.Q: Where can this rotary gear pump be installed?

A: It is designed for horizontal foot-mounted installation, facilitating placement in industrial spaces such as factories, oil depots, or fuel transfer stations.Q: What is the process for selecting the correct pump size and gear ratio?

A: Selection depends on required discharge capacity, inlet/outlet size, fluid properties, and desired output speed. Consulting the distributor or supplier with your specific application data ensures optimal sizing and gear ratio for your operation.Q: How efficient is this rotary gear pump during operation?

A: The pump operates with up to 85% efficiency, ensuring energy savings and reliable fluid movement in demanding conditions.Q: What benefits does the precision-machined construction provide?

A: Precision machining results in reduced internal leakage, longer service life, consistent performance, and minimal maintenance, ensuring cost-effective operation over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+