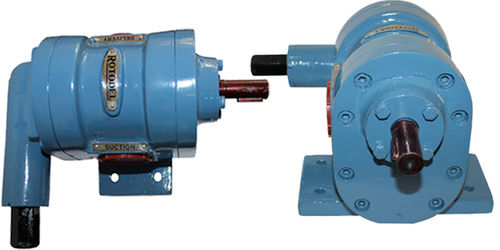

Internal Gear Pump

Product Details:

- Gear Type Helical or Spur

- Material Cast Iron

- Processing Type Precision Casting

- Gear Tooth Profile Internal Gear

- Gearing Arrangement Internal

- Direction Bidirectional

- Output Torque High Torque

- Click to view more

Internal Gear Pump Price And Quantity

- 1 Piece

- Horizontal Foot Mounted

- Up to 5 meters

- Handling viscous liquids, oil transfer, food processing, chemical transfer

- 1" to 3"

- Mechanical Seal or Gland Packing

- Antifriction Ball Bearings

- Up to 200°C

- 300 LPM

- 10 kg/cm²

- Cast Iron/SS

Internal Gear Pump Product Specifications

- 1440 RPM

- Up to 10 HP

- Up to 90%

- Internal Gear

- Helical or Spur

- 1440 RPM

- Internal

- High Torque

- Bidirectional

- Cast Iron

- Precision Casting

- 220-440 V

- Horizontal Foot Mounted

- Up to 5 meters

- Handling viscous liquids, oil transfer, food processing, chemical transfer

- 1" to 3"

- Mechanical Seal or Gland Packing

- Antifriction Ball Bearings

- Up to 200°C

- 300 LPM

- 10 kg/cm²

- Cast Iron/SS

Internal Gear Pump Trade Information

- as per order Per Week

- as per order Week

Product Description

Internal Gear Pump are majorly used in chemical installations to pump high viscosity fluids. These pumps are fixed displacement, which means they pump a constant amount of fluid for each revolution. Some gear pumps are designed to function as either a pump or a motor. The product is meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic power applications. The product very less power supply and can be customized as per the requirement. These Internal Gear Pump are basically valves which saves the end machine against the over load.

| Casing: | Cast iron |

| Idler: | Cast iron, Stainless steel, Steel |

| Rotor: | Cast iron, Nodular iron, Stainless steel |

| Max. capacity: | 130 m3/h |

| Max. differential pressure: | 16 bar |

| Max. temperature: | 300°C |

| Max. viscosity: | 80000 |

| Shaft seal: | Packed gland without lantern ring. Shaft trust on bush bearing inside and ball bearing outside the liquid. |

|

| Packed gland with lantern ring, single or double mechanical seal OR cartridge seals. |

|

| Single mechanical seal. Shaft trust on roller bearing and ball bearing outside the liquid. |

Efficient Handling of Viscous and Corrosive Fluids

Our Internal Gear Pump is perfectly suited for industries handling viscous fluids or requiring hygienic fluid transfer, like oil, chemicals, and food processing. Its high flow rate of up to 300 LPM and robust pressure handling make it ideal for applications demanding both reliability and precision. Its efficient gearing and durable housing ensure consistent operation under demanding conditions.

Precision Engineering & Superior Durability

Fabricated from cast iron or stainless steel using advanced precision casting methods, this pump boasts excellent durability. The incorporation of antifriction ball bearings further extends service life and minimizes maintenance. Whether for daily industrial use or critical export operations, this pump stands out for its reliability and design.

Versatility in Industrial Applications

With bidirectional flow, a variety of seal options, and compatibility with both helical and spur gears, this internal gear pump is designed for flexibility. It is capable of transferring a range of fluids at temperatures up to 200C. Suitable for a wide array of industries including oil transfer, chemical processing, and food manufacturing.

FAQs of Internal Gear Pump:

Q: How does the internal gear pump efficiently handle viscous liquids in industrial applications?

A: The internal gear pump utilizes precision-cast gears and a robust motor to generate high torque, ensuring smooth and consistent flow of viscous liquids. Its design allows for minimal slippage and optimal efficiency, handling substances like oil, chemicals, and syrups even at elevated viscosities.Q: What are the key benefits of choosing a horizontal foot-mounted internal gear pump for my facility?

A: The horizontal foot-mounted design offers stability, ease of installation, and simplified maintenance. It aligns the pump perfectly with pipeline systems, reducing vibration and prolonging component lifemaking it ideal for continuous operation in demanding industrial environments.Q: When should I opt for mechanical seals versus gland packing in this pump?

A: Mechanical seals are ideal for applications where leakage minimization and longer service intervals are crucial, such as chemical or food transfer. Gland packing may be preferable when cost-effectiveness and ease of onsite adjustment are required, especially in less critical or lower-pressure contexts.Q: Where is this internal gear pump commonly installed and utilized?

A: This pump is widely used in industries such as oil refineries, chemical processing plants, food manufacturing units, and facilities requiring the transfer of viscous or sensitive liquids. Its robust construction and flexibility make it a top choice for industrial distributors, exporters, and suppliers across India.Q: How is the process of maintenance simplified for users of this internal gear pump?

A: Thanks to the antifriction ball bearings, precision-cast internals, and standardized mounting, routine maintenance is straightforward. Regular checks on seals, bearings, and alignment are recommended, and most wear parts can be easily accessed and replaced as needed, minimizing downtime.Q: What materials and gearing arrangements can I select for specific application requirements?

A: Weve engineered the pump in cast iron for general industry and stainless steel for applications with stringent hygiene or corrosion requirements. You also have the option between helical or spur-shaped internal gears according to the specific flow characteristics or mechanical needs of your process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+