Pressure Booster Systems - Hydro pneumatic Systems

Product Details:

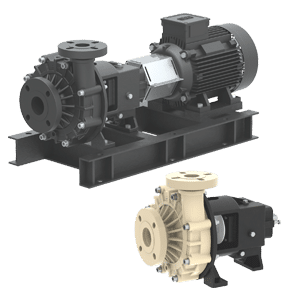

- Theory Centrifugal

- Flow Rate Upto 500 m/hr

- Material Cast iron, Stainless steel

- Structure Compact skid mounted

- Suction Type Hydro pneumatic

- Volute Type Standard

- Nozzle Location Horizontal

- Click to view more

Pressure Booster Systems - Hydro pneumatic Systems Price And Quantity

- 1 , , Piece

Pressure Booster Systems - Hydro pneumatic Systems Product Specifications

- Horizontal

- Horizontal

- Cast iron, Stainless steel

- Electric

- Domestic water supply, Commercial complexes, Hospitals, Hotels, Irrigation

- 0C to 80C

- Hydro pneumatic

- 25 mm to 150 mm

- Standard

- 1450/2900 RPM

- Upto 16 bar (variable)

- Centrifugal

- Upto 500 m/hr

- Compact skid mounted

Pressure Booster Systems - Hydro pneumatic Systems Trade Information

- as per oder Per Week

- as per oder Week

Product Description

Pressure Booster Systems - Hydro pneumatic Systems:

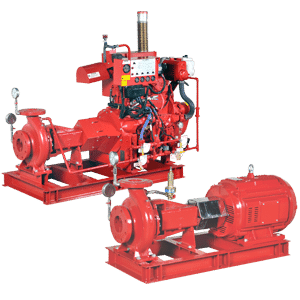

Lubi Aquapack 1000 booster sets consist of 2 to 4 identical vertical multistage (LCR) pumps mounted in parallel on a common base frame, control cabinet with motor protection

and integrated LE 1000 series controller.

These pumps are automatically operated according to system requirement by means of pressure switches (one for each pump). The setting of the pressure switches have to

be within the optimal performance area of each pump model. Automatic operation of one or more pumps with VFD control is optional.

Aquapack 1000 booster sets are supplied as complete, preassembled and tested systems including suction and discharge manifolds, isolating valves, non-return valves,

pressure gauge and pressure switches.

Applications:

Lubi Aquapack 1000 booster sets are designed for the transfer and pressure boosting of clean water for community water supply, apartment complex, hotels, hospitals, industries, commercial buildings, schools, etc.

Features:

The state-of-the-art features introduced into this new vertical multistage pump generation offer the following benefits:

High efficiency: Minimized energy cost

Low NPSH: Improves suction capability

Air handling: Reduces risk of dry-running

Spacer coupling: Allows easy disassembly of motor from pump (for 11 kW motor onwards)

Sleeve sealing: Provides high resistance to pressure pulses and withstands temperature fluctuations as well as external forces

Tungsten carbide: Wear resistance, improved dry- running capability and handling of thermal shocks enable longer operating time bearings

Reinforced shaft: Strong axial locking force and high torque lock system enable robust and reliable operation of rotating assembly lock ring

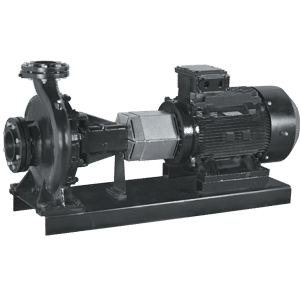

Efficient Water Delivery for Every Need

Our hydro pneumatic pressure booster systems cater to diverse requirements, from residential complexes to hotels and commercial facilities. Featuring variable pump sets and automatic controls, they guarantee constant pressure regardless of fluctuating demand. Whether for daily water supply or specialized irrigation, these systems ensure reliability and efficiency.

Plug-and-Play Installation

The entire unit comes skid-mounted with all key components pre-assembled, allowing for rapid on-site installation. With a user-friendly design and included accessories such as pressure gauges, control panels, and NRVs, setup is streamlined and hassle-free. Professional onsite support and installation services are available throughout India.

FAQs of Pressure Booster Systems - Hydro pneumatic Systems:

Q: How does the hydro pneumatic pressure booster system maintain consistent water pressure?

A: The system utilizes automatic on/off operation controlled by a pressure switch or electronic controller. This ensures the pumps activate only when pressure drops below a set point, maintaining steady water pressure throughout the network regardless of varying demand.Q: What types of environments and applications are suitable for these pressure booster systems?

A: These systems are ideal for domestic water supply in homes, apartment complexes, commercial establishments, hotels, hospitals, and large-scale irrigation. Their robust design and adaptable flow rates make them versatile for both residential and industrial uses.Q: When should I consider installing a multi-pump hydro pneumatic system instead of a single-pump unit?

A: A multi-pump configuration is recommended when your application requires higher reliability, greater flow rates, or redundancy for continuous operation. For example, larger buildings or complexes with fluctuating peak demands benefit from a multi-pump setup.Q: Where can these booster systems be installed, and how much space do they require?

A: Designed for skid-mounted, plug-and-play installation, these units can be placed in utility rooms, pump houses, or dedicated plant rooms. Their compact, base-plate-mounted structure minimizes footprint while allowing flexible placement.Q: What is the process for setting up and starting the pressure booster system?

A: Installation involves connecting the inlet and outlet to the water lines, supplying power (220V or 415V, 50 Hz), and configuring the pressure controls. The unit arrives pre-assembled with a control panel, NRV, and pressure tank. Professional onsite installation and commissioning support are included to ensure seamless operation.Q: How do the pressure tanks with food-grade membrane benefit water quality?

A: Pressure tanks fitted with food-grade membranes prevent water contamination by isolating the water from the tank shell and components, ensuring that stored water remains clean and safe for domestic or commercial use.Q: What ongoing support or maintenance services are available?

A: Onsite installation and after-sales support are provided, with routine maintenance, troubleshooting, and spare part supply accessible through our pan-India network of distributors and service professionals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+