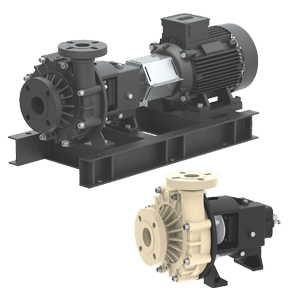

Chemical Process Pumps - Non Metallic

Product Details:

- Theory Centrifugal Pump

- Flow Rate Up to 80 m/hr

- Material Polypropylene, PVDF, UHMWPE (Non Metallic)

- Structure Close coupled/Monoblock type

- Suction Type Self Priming

- Volute Type Single

- Nozzle Location End Suction, Top Discharge

- Click to view more

Chemical Process Pumps - Non Metallic Price And Quantity

- 1 , , Piece

Chemical Process Pumps - Non Metallic Product Specifications

- Electric Motor Driven

- None (Electric)

- Close coupled/Monoblock type

- 25mm to 100mm

- Chemical handling, Acid transfer, Corrosive liquids, Effluent treatment

- -10C to 100C

- Polypropylene, PVDF, UHMWPE (Non Metallic)

- Up to 80 m/hr

- up to 2900 rpm

- Horizontal

- Self Priming

- Up to 5 kg/cm2

- End Suction, Top Discharge

- Centrifugal Pump

- Single

Chemical Process Pumps - Non Metallic Trade Information

- as per oder Per Week

- as per oder Week

Product Description

Chemical Process Pumps - Non-Metallic:

Applications;

Chemical process

Pharmaceutical

Food & Beverage processing

Steel plants

Automobile

Marine/Sea water

Water supply

Booster service

Cooling water

Water treatment/Purification

OEM.

Features:

State-of-the art compact design

Easy and simple install

User-friendly operation

Quiet running

Reliable and robust construction

Back pull-out design which simplifies inspection and maintenance

Rotating parts are dynamically balanced which ensure vibration free performance and enhanced life

High performance hydraulics

TECHNICAL DATA:

Capacity [Q]: 90 M^3 /Hr.

Head [H] upto: 60 Meters

Motor Power [P] upto: 22 KW 30 HP

Viscosity upto: 150 mPas (cP)

Suction lift upto: 8 m (26 ft) with priming chamber*

Maximum Working Pressure: 10 bar (145 psi)

Maximum Specific Gravity [SG]: 1.8 - 3

Minimum Continuous Flow [MCF]: 2.5 m /hr (11 US gpm)

Maximum Temperature: GFRPP: 90C (194F), NORYL : 82C (180F), PVDF: 104C (220F)

Suction & Delivery Connection: PN16, PN25, Class 250, BSP

Shaft Seal: Single (SPB/SPS) & Double (DPS) Mechanical Seals

Bearings Lubrication: Rolling Element Bearings Oil

Motor Compatibility: IE-2 / FLAME PROOF

Operating Frequency 50 Hz. up to up to up to up to up to 150 mPas (cP)

Robust Non-Metallic Construction

Our chemical process pumps are crafted in high-grade Polypropylene, PVDF, and UHMWPE to ensure exceptional resistance to corrosion, even during prolonged exposure to aggressive chemicals and effluents. The non-metallic structure extends pump life and reduces downtime from material degradation, perfect for challenging industrial environments.

Versatile Application and High Performance

Designed for chemical handling, acid transfer, corrosion-prone sites, and effluent management, these pumps efficiently manage flows up to 80 m/hr and heads up to 38 m. The self-priming volute type, low noise, and robust mechanical sealing enhance reliability for continuous operation in demanding settings.

FAQs of Chemical Process Pumps - Non Metallic:

Q: How does the non-metallic construction benefit chemical process pump applications?

A: Non-metallic materials such as Polypropylene, PVDF, and UHMWPE offer superior chemical resistance and durability, preventing corrosion and degradation when handling a wide range of aggressive chemicals and acids.Q: What type of impeller and sealing arrangement is used in these pumps?

A: These pumps use fully open, non-clog impellers suitable for solid handling up to 10 mm, and provide mechanical seals for leakage-free operation, with gland packing available as an optional feature.Q: When is a chemical process pump with self-priming capability most advantageous?

A: Self-priming pumps are especially useful when suction conditions are difficult or when frequent restarting is required, as they eliminate the need for manual priming and reduce operational downtime.Q: Where are these pumps commonly installed and used?

A: They are typically installed in chemical factories, acid transfer stations, effluent treatment plants, and other industrial sites requiring safe handling of corrosive liquids. The foot-mounted design and horizontal shaft orientation facilitate floor-level installation.Q: What is the process for selecting the appropriate model for my application?

A: Assess fluid characteristics, required flow rate (up to 80 m/hr), head (up to 38 m), solid size, temperature, and pH range. Then, choose the pump material, connection type, and nozzle configuration that best suits your unique requirements.Q: Can I customize the pumps color or nozzle location?

A: Yes, these pumps offer customizable color options (blue, white, or others on request) and flexible nozzle locations for end suction and top discharge to match your specific installation needs.Q: What are the main usage benefits of this pump design?

A: The pumps provide highly reliable, efficient chemical transfer, minimal downtime from clogging or corrosion, easy maintenance, and low operational noise. The conformity to DIN/ISO standards ensures global compatibility and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+