Vertical Multistage Pumps

Product Details:

- Theory Centrifugal Pump

- Flow Rate Up to 80 m/h

- Material Stainless Steel (AISI 304/316), Cast Iron End Covers

- Structure Multistage, Inline

- Suction Type Axial Flow

- Volute Type Single Volute

- Nozzle Location Top Centerline

- Click to view more

Vertical Multistage Pumps Price And Quantity

- 1 Piece

Vertical Multistage Pumps Product Specifications

- Electric

- Axial Flow

- Multistage, Inline

- Vertical

- Centrifugal Pump

- Top Centerline

- Up to 25 bar

- Booster Systems, Water Treatment, Pressure Washing, Irrigation, Industrial Processes

- N/A (Electric Drive)

- -15C to 120C

- DN 25 to DN 100 mm

- Stainless Steel (AISI 304/316), Cast Iron End Covers

- Up to 80 m/h

- Single Volute

- 2900 rpm

Vertical Multistage Pumps Trade Information

- as per oder Per Week

- as per oder Week

Product Description

Applications:

Water supply

Filtration and transfer at waterworks

Distribution from waterwork

Pressure boosting in high-rise buildings, hotels, etc.

Pressure boosting for industrial water supply

Industry Pressure boosting in

Process-water systems

Washing and cleaning systems

Vehicle washing tunnels

Fire-fighting systems

Liquid transfer in

Cooling and air-conditioning systems (refrigerants)

Boiler feed and condensate systems

Machine tools (cooling lubricants)Aquafarming Transfer of

Oils and alcohaols

Acids and alkalis

Glycol and coolantsWater treatment

Ultra-filtration systems

Reverse osmosis systems

Softening, ionizing, demineralizing systems

Distillation systems

Separators

Swimming bathsIrrigation

Field irrigation (flooding)

Sprinkler irrigation

Drip-feed irrigation

Features:

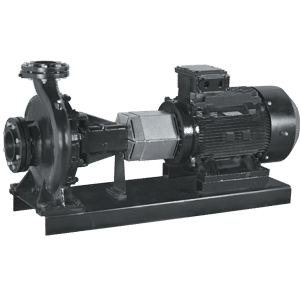

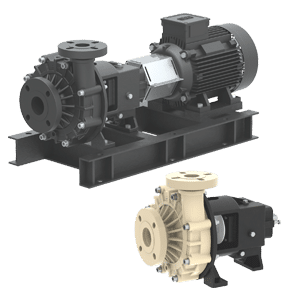

The LCR pumps are non-self-priming, vertical multistage centrifugal pumps.

The pump consists of a base and a pump head. The chamber stack and the outer sleeve are secured between the pump head and the base by means of tie bolts.

The base has suction and discharge connections on the same level (in-line).

All pumps are equipped with a maintenance-free mechanical shaft seal of the cartridge type as standard

LCR, LCRI and LCRN pumps are fitted with a totally enclosed, fan-cooled, 2-pole motor with principal dimensions in accordance with the EN standards.

Electrical tolerances according to EN 60034.

High Performance and Reliability

Designed with deep groove ball bearings and flexible couplings, these vertical multistage pumps offer trouble-free operation and reliable performance in demanding environments. The structure allows for smooth, quiet running below 75 dB(A), ensuring minimal disruption in industrial and commercial installations.

Versatile Applications

Suitable for a wide range of tasks, these pumps are ideal for booster systems, water purification plants, irrigation needs, pressure washing, and several industrial processes. Their robust build and high-pressure capability make them an excellent choice for both utility and process water handling.

Robust Construction

Made from high-grade stainless steel (AISI 304/316) and cast iron end covers, these pumps resist corrosion and withstand harsh operating conditions. The vertical inline configuration aids in saving floor space and simplifies piping arrangements.

FAQs of Vertical Multistage Pumps:

Q: How do vertical multistage pumps operate in booster systems?

A: These pumps utilize multiple staged impellers to incrementally increase water pressure, making them highly effective for booster systems needing consistent and elevated pressure across buildings or industrial processes.Q: What is the benefit of a mechanical seal in these pumps?

A: Mechanical seals minimize leakage and provide enhanced reliability, especially in high-pressure and temperature conditions, reducing maintenance intervals and ensuring continuous operation.Q: When should manual or self-priming be used during pump operation?

A: Initial priming can be performed manually if self-priming is unavailable, particularly during the first operation. After this, the pumps flooded suction and design generally maintain prime for subsequent use.Q: Where is the optimal installation location for these vertical inline pumps?

A: These pumps are best installed in vertical inline positions, with suction at the axial flow top centerline nozzle, which simplifies integration into existing pipework and conserves floor space in plant rooms.Q: What is the typical process for maintaining these multistage pumps?

A: Routine inspections of bearings and seals, checking for noise and vibration, and monitoring electrical connections are recommended to ensure longevity and optimal performance. Their heavy-duty construction allows for longer service intervals.Q: How does the flexible coupling contribute to pump usage?

A: Flexible couplings dampen vibration and compensate for slight misalignments between the pump and motor, thereby safeguarding internal components and enhancing the units overall durability.Q: What major benefits do users in India gain from these pumps?

A: Users benefit from high efficiency, robust materials adapted to local water quality, pressure handling up to 25 bar, and compatibility with standard industrial electrical supplies, making them viable for a vast range of applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+