Vertical Inline Pumps

Product Details:

- Theory Centrifugal Pump

- Flow Rate Up to 400 m/hr

- Material Cast Iron / Stainless Steel

- Structure Vertical Inline single-stage centrifugal

- Suction Type Single Suction

- Volute Type Single Volute

- Nozzle Location Inline

- Click to view more

Vertical Inline Pumps Price And Quantity

- 1 Piece

Vertical Inline Pumps Product Specifications

- Inline

- Up to 400 m/hr

- None (Electric Driven)

- Centrifugal Pump

- Vertical Inline single-stage centrifugal

- Up to 16 bar

- 1450 to 2900 RPM

- Electric Motor Driven

- Single Suction

- Cast Iron / Stainless Steel

- 50 mm to 200 mm

- Water supply, HVAC, fire fighting, industrial process, booster systems

- Up to 120C

- Single Volute

- Vertical

Vertical Inline Pumps Trade Information

- as per oder Per Week

- as per oder Week

Product Description

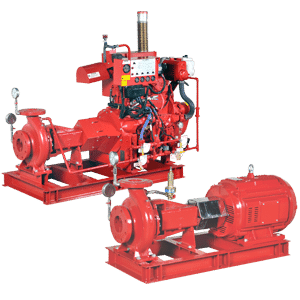

Vertical Inline Pumps;

LVI pumps are non-self-priming, single-stage, vertical in-line, close- coupled type centrifugal pumps having radial suction and radial discharge port. Vertical in line pump is designed for non-explosiv liquids which are clean, and thin without any solid particles.

A viscous liquid affects the pump performance in the following ways.

The power consumption of the pump will increase with increase in viscosity. This will require a larger motor for the pump.

Head, discharge & pump efficiency will reduce.

The volute casing of Vertical in line pump is designed to be robust in construction to take the undue stresses offered by the pipe work. They have a radial suction port and radial discharge port. Standard flanges are PN 16 as per EN 1092-2 and PN 25 as per DIN standard EN 1092-2. ANSI 125 and ANSI 250 as per ASME B16.1 are available on request. The volute casing of Vertical in line pump is provided with a priming & drain hole closed by plugs. The impellers are closed impellers with extra smooth surface finish and machined completely from outside to ensure high efficiency. The direction of rotation of impeller is clock wise when viewed from the motor driving end. They are dynamically balanced to grade 6.3 of ISO 1940. All impellers of Vertical in line pump can be trimmed to adopt them for the duty point requested by the customers

Applications:

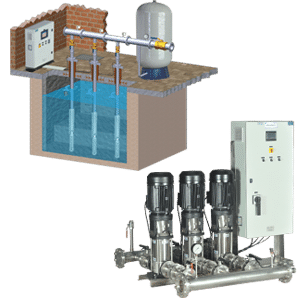

Cooling & heating systems.

Pressure boosting systems.

Industrial applications.

Water supply.

Fire protection systems

Features:

Vertical in-line pumps offer largest floor space saving compared to End suction & Horizontal split case pumps.

The in-line construction offers easy pipe work. Pipe hangers sized for the weight of the pump, piping & fittings offers adequate supports for most installations.

The inlet passages of the volute casing are of liberal size & have flow straightening vanes to provide excellent suction performance and extremely quiet operation.

Standard flanges for suction and discharge ports will be PN 16 as per DIN standard EN 1092-2 and PN 25 as per DIN standard EN 1092-2. ANSI 125 and ANSI 250 as per ASME B16.1 are available on request.

These pumps are close coupled pumps with TEFC squirrel cage induction motors with main dimensions complying with IEC standards.

These pumps are available with mechanical shaft seal only.

These pumps have the discharge range up to 600 m³/hr and head range up to 150 metres. Motor ratings are up to 132 kW.

The pump impellers are dynamically balanced to grade 6.3 of ISO 1940.

These pumps are available with our standard range of motors complying with EFF2 motors. They can also be supplied with EFF1 motors on request

Reliable Performance for Demanding Applications

Designed with a closed impeller and single volute, these vertical inline pumps deliver exceptional hydraulic performance for water supply, HVAC, fire suppression, and industrial processes. The stainless steel shaft, heavy-duty ball bearings, and mechanical seal ensure durable, low-vibration operation even under challenging conditions.

Easy Installation and Maintenance

Featuring an inline, flanged mounting configuration compliant with both DIN and ANSI standards, these pumps are straightforward to install and service. Their vertical structure saves valuable floor space and the epoxy coated finish provides enhanced corrosion protection for extended operational life.

Safety and Efficiency Assured

Electric motor-driven operation with IP55 protection safeguards against dust and water ingress, ensuring reliable, energy-efficient performance. Low noise levels and robust construction make these pumps ideal for noise-sensitive or high-demand environments where consistent operation is critical.

FAQs of Vertical Inline Pumps:

Q: How are these vertical inline pumps installed and maintained?

A: Installation is made easy with the inline, flanged mounting system that fits DIN and ANSI standards. Maintenance is straightforward thanks to the accessible layout, high-grade mechanical seals, and robust components that can be inspected or replaced without dismantling the entire system.Q: What types of applications are suitable for these pumps?

A: These pumps are ideal for water supply, HVAC circulation, fire fighting, booster systems, and a variety of industrial process applications. They are also suitable for use wherever low-noise, reliable centrifugal pumps are needed to handle clean water or similar fluids.Q: When should I choose a closed impeller and single-volute pump?

A: A closed impeller is best selected for clean liquids where efficiency and minimized wear are desired. The single-volute design offers stable flow and performance, making it suitable for booster, circulation, and process applications requiring consistent operation and lower maintenance.Q: Where can these pumps be installed?

A: Thanks to their inline and vertical configuration, they can be installed directly into pipeline systems within buildings, factories, or infrastructure settings. Their compact footprint makes them suitable for confined spaces, mechanical rooms, and pump skids.Q: What are the benefits of having IP55 motor protection and epoxy coating?

A: IP55 motor protection guards against dust and water jets, enhancing the longevity and safety of the electric motor in demanding environments. The epoxy coating further protects external metal surfaces from corrosion, extending the pumps service life.Q: How does the material selection impact pump durability?

A: Using cast iron or stainless steel for key pump components ensures high mechanical strength, resistance to corrosion, and compatibility with a variety of process fluids. Stainless steel shafts and heavy-duty ball bearings further contribute to long-lasting, trouble-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+