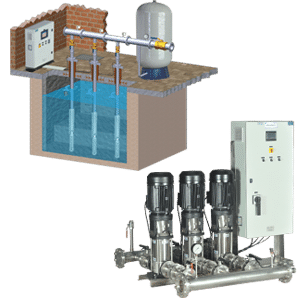

Pressure Booster Systems - Hydro pneumatic Systems

Product Details:

Pressure Booster Systems - Hydro pneumatic Systems Price And Quantity

- 1 Piece

Pressure Booster Systems - Hydro pneumatic Systems Trade Information

- as per oder Per Week

- as per oder Week

Product Description

Pressure Booster Systems - Hydro pneumatic Systems:

Lubi Aquapack 1000 booster sets consist of 2 to 4 identical vertical multistage (LCR) pumps mounted in parallel on a common base frame, control cabinet with motor protection

and integrated LE 1000 series controller.

These pumps are automatically operated according to system requirement by means of pressure switches (one for each pump). The setting of the pressure switches have to

be within the optimal performance area of each pump model. Automatic operation of one or more pumps with VFD control is optional.

Aquapack 1000 booster sets are supplied as complete, preassembled and tested systems including suction and discharge manifolds, isolating valves, non-return valves,

pressure gauge and pressure switches.

Applications:

Lubi Aquapack 1000 booster sets are designed for the transfer and pressure boosting of clean water for community water supply, apartment complex, hotels, hospitals, industries, commercial buildings, schools, etc.

Features:

The state-of-the-art features introduced into this new vertical multistage pump generation offer the following benefits:

High efficiency: Minimized energy cost

Low NPSH: Improves suction capability

Air handling: Reduces risk of dry-running

Spacer coupling: Allows easy disassembly of motor from pump (for 11 kW motor onwards)

Sleeve sealing: Provides high resistance to pressure pulses and withstands temperature fluctuations as well as external forces

Tungsten carbide: Wear resistance, improved dry- running capability and handling of thermal shocks enable longer operating time bearings

Reinforced shaft: Strong axial locking force and high torque lock system enable robust and reliable operation of rotating assembly lock ring

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+