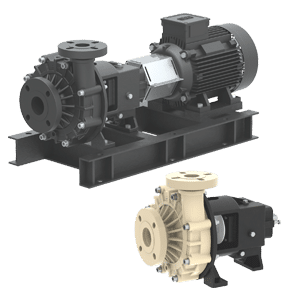

End Suction Long Coupled Pumps

Product Details:

- Theory Centrifugal Pump

- Flow Rate Up to 1500 m/h

- Material Cast Iron / Stainless Steel / Bronze

- Structure Long Coupled, Single Stage

- Suction Type End Suction

- Volute Type Single Volute

- Nozzle Location Top Centerline Discharge, Horizontal Suction

- Click to view more

End Suction Long Coupled Pumps Price And Quantity

- 1 , , Piece

- Closed / Semi-Open

- Corrosion Resistant

- DIN / ANSI

- Clockwise (when viewed from the driving end)

- As per ISO 5199 / API 610

- Heavy Duty Antifriction Ball Bearings

- Up to 20 mm

- Baseplate Mounted

- Flexible Coupling

- Mechanical Seal / Gland Packing

End Suction Long Coupled Pumps Product Specifications

- Long Coupled, Single Stage

- Horizontal

- -10C to +140C

- Up to 1500 m/h

- Top Centerline Discharge, Horizontal Suction

- 50 mm to 300 mm

- Electric Motor / Diesel Engine

- Up to 16 bar

- Cast Iron / Stainless Steel / Bronze

- End Suction

- Water supply, HVAC, Irrigation, Firefighting, Industrial process

- Single Volute

- Up to 3500 RPM

- Centrifugal Pump

- Direct Coupled

- Closed / Semi-Open

- Corrosion Resistant

- DIN / ANSI

- Clockwise (when viewed from the driving end)

- As per ISO 5199 / API 610

- Heavy Duty Antifriction Ball Bearings

- Up to 20 mm

- Baseplate Mounted

- Flexible Coupling

- Mechanical Seal / Gland Packing

End Suction Long Coupled Pumps Trade Information

- as per oder Per Week

- as per oder Week

Product Description

End Suction Long Coupled Pumps:

Capacity: upto 660 M^3/Hr.

Head: Upto 158 Meters

Applications:

Water Supply.

Pressure boosting for high rise buildings, hotels industry etc.

Industrial washing & cleaning systems.

Fire Protection systems.

Cooling & Air Conditioning systems.

Boiler feed and condensate transfer system.

Irrigation systems for fields including sprinkler & drip

irrigation systems

Features:

The pumps are non self priming horizontal end suction pumps with axial suction port and radial discharge ports.

Standard flanges for suction and discharge ports will be PN 16 as per DIN standard EN 1092-2, PN 25 as per DIN standard EN 1092-2, ANSI 125 and ANSI 250 as per ASME B16.1 are available on request.

Performance and dimensions comply to ISO 2858.

These pumps are long coupled pumps with TEFC squirrel cage induction motor with main dimensions complying to IEC standards and mounting designation B3 (IM 1001).

These pumps are available with gland packing as well as mechanical shaft seal.

The pump impellers are dynamically balanced to grade 6.3 of ISO 1940.

These pumps and motors are available with fabricated steel base frame according to EN 23661.

These pumps are available with standard range of IE2 motors.

Robust Construction and Versatile Applications

Designed with a long-coupled, single-stage structure, these pumps cater to demanding environments, supporting both electric motor and diesel engine drives. The corrosion-resistant finish and flexible coupling ensure long-term operation and minimal maintenance, making the pump suitable for water treatment plants, firefighting systems, agricultural irrigation, and industrial installations.

Precision Engineered for Performance

Adhering to ISO 5199 and API 610 testing standards, each pump is tested to guarantee high efficiency, solid handling up to 20 mm, and consistent delivery. The closed/semi-open impeller options and single volute design lend adaptability for varying feed conditions and challenging fluids.

FAQs of End Suction Long Coupled Pumps:

Q: How does the pump handle solid-laden fluids or debris?

A: These pumps are engineered to handle solids up to 20 mm, making them suitable for applications where suspended particulates may be present, such as in irrigation or certain industrial processes. The impeller and volute are specifically designed to minimize clogging and ensure consistent operation.Q: What are the main benefits of a long coupled, baseplate mounted pump design?

A: Long coupled pumps offer greater alignment accuracy and easier maintenance compared to close-coupled units. The baseplate mounting absorbs vibrations and extends pump life, while also simplifying the alignment procedure during installation or servicing.Q: When is it appropriate to select mechanical seal versus gland packing sealing?

A: Mechanical seals are preferable for higher pressure, high-temperature, or abrasive duty environments, enhancing leakage control and minimizing maintenance. Gland packing is often chosen for non-critical applications or when cost efficiency and ease of replacement are key priorities.Q: Where should these end suction pumps be installed for optimal performance?

A: For best results, install these pumps in dry, accessible locations with a secure and well-leveled foundation. The horizontal shaft orientation and top centerline discharge allow for straightforward piping layouts and efficient air expulsion, crucial for applications such as water supply and HVAC.Q: What is the process for coupling the pump to a power source?

A: These pumps use a flexible coupling for direct connection to either an electric motor or diesel engine. This coupling helps compensate for slight misalignments and reduces transmission of vibrations, fostering smoother and safer operation.Q: How do these pumps comply with international standards and why is this beneficial?

A: Tested according to ISO 5199 and API 610, these pumps demonstrate quality, high reliability, and global acceptance. This compliance assures users of rigorous performance and safety benchmarks, necessary for both industrial and municipal installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+