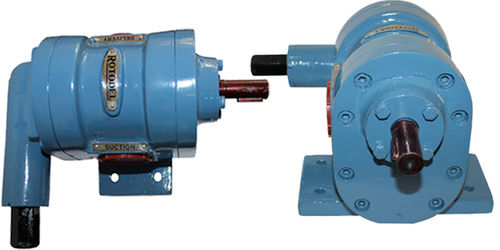

HGN Rotary Gear Pump

Product Details:

- Gear Type Helical Gears

- Material Cast Iron

- Processing Type Standard

- Gear Tooth Profile Spur

- Gearing Arrangement External

- Direction Clockwise / Anticlockwise

- Output Torque High Torque

- Click to view more

HGN Rotary Gear Pump Price And Quantity

- 1 Piece

- Anti-Corrosive Paint

- Flanged / Screwed

- 10 to 500 LPM

- EN8 / SS304

- 1/2" to 3"

- Foot Mounted

- Up to 10 kg/cm2

- Lube Oil, Bitumen, Diesel, and Various Viscous Liquids

- Up to 200°C

- Mechanical Seal / Gland Packing

HGN Rotary Gear Pump Product Specifications

- Cast Iron

- Dependent on application

- Clockwise / Anticlockwise

- High Torque

- Spur

- 1440 RPM

- Up to 85%

- Standard

- External

- 415V AC

- Helical Gears

- Up to 15 HP

- Anti-Corrosive Paint

- Flanged / Screwed

- 10 to 500 LPM

- EN8 / SS304

- 1/2" to 3"

- Foot Mounted

- Up to 10 kg/cm2

- Lube Oil, Bitumen, Diesel, and Various Viscous Liquids

- Up to 200°C

- Mechanical Seal / Gland Packing

HGN Rotary Gear Pump Trade Information

- as per order Per Week

- as per order Week

Product Description

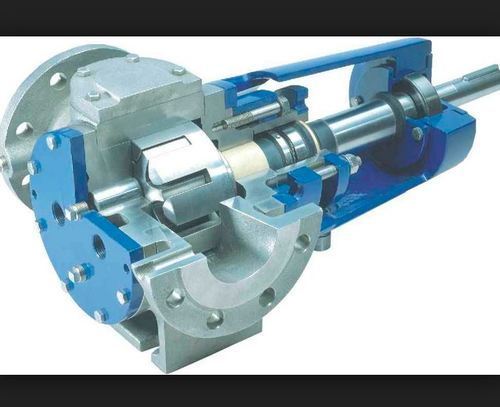

Rotary Gear Pump Type HGN

Features:

Size from 1/2" to 3" BSP

Capacity from 20 LPM to 500 LPM max.

Working Pressure 11KG/CM2

Temp 90°C

Viscocity, 10,000 CST (Please refer us)

Compact

Low Noise

Efficient

Easy Maintainable

Cost Economical

Applications: 'ROTODEL' Rotary gear pumps are useful for handling viscouse liquids i.e.all kind of oils, viscous chemicals & food application. Following liquid can be handle with Rotodel Pump.

All kind of mineral oils.

All kind of vegetable oils.

Coal tar, Bitumen, asphalts

Paints & varnish

Sugar molasses & syrups

Printing inks & Dyes.

All kind of fish & animal oils.

Glycerine & glycole.

Fuel oil, Diesel oil & funace oil

Soap solution & lard.

Glue.

Viscous chemicals.

Rotodel Rotary gear pumps finds wide application in Power Plant, Steel Mills, Refineries, Oil Storage Installation etc.

Models - Sizes:

Rotodel Gear Pump HGN 050

Rotodel Gear Pump HGN 075

Rotodel Gear Pump HGN 100

Rotodel Gear Pump HGN 125

Rotodel Gear Pump HGN 150

Rotodel Gear Pump HGN 200

Rotodel Gear Pump HGN 250

Rotodel Gear Pump HGN 300

Design improvement is a continuous process therefore information in this catalogue is subject to change without notice

Reliable Performance for Viscous Liquids

The HGN Rotary Gear Pump excels in handling a wide spectrum of viscous liquids, such as lube oil, bitumen, and diesel. Its high discharge pressure capability and efficient spur gear design ensure consistent flow and reliability, even at high temperatures up to 200C. With robust construction and precise engineering, users get dependable operation for industrial fluid processing.

Versatile Installation Options

Designed with flexibility in mind, this pump offers foot-mounted installation for easy integration into various setups. Dual connection typesflanged and screwedallow for seamless adaptation to existing pipeline systems. Whether requiring clockwise or anticlockwise rotation, the pump fits diverse application needs throughout lubrication, fluid transfer, and bitumen handling sectors.

FAQs of HGN Rotary Gear Pump:

Q: How is the HGN Rotary Gear Pump installed and connected to pipelines?

A: The pump is foot-mounted, providing easy and stable installation. It offers flanged or screwed connections, which allow you to connect the unit securely to your existing pipeline systems, accommodating both clockwise and anticlockwise rotation as needed.Q: What types of liquids can this pump handle efficiently?

A: This rotary gear pump is designed to process lube oil, bitumen, diesel, and a variety of viscous liquids, making it suitable for lubrication, transfer, and bitumen handling in industrial environments.Q: When is the use of mechanical seal versus gland packing recommended?

A: A mechanical seal is preferred for applications requiring higher leak resistance and minimal maintenance, especially at elevated temperatures. Gland packing is suitable for less demanding scenarios where regular maintenance is acceptable.Q: Where can the HGN Rotary Gear Pump be utilized in industry?

A: This pump finds use in the lubrication systems, bitumen transfer stations, diesel fuel handling units, and any process requiring the movement of viscous fluids. Its compatible voltage and robust build make it suitable for various industrial infrastructures across India.Q: What is the process for maintenance of this gear pump?

A: Regular maintenance involves inspection of seals (mechanical or gland packing) for wear, checking for leaks, and ensuring anti-corrosive body coating integrity. Shaft and gear condition should be periodically reviewed to maintain optimal efficiency and prolong pump life.Q: How does the pumps high torque and efficiency benefit industrial operations?

A: With up to 85% efficiency and high output torque, the pump handles demanding workloads and provides reliable performance, reducing energy consumption and ensuring consistent fluid transfer even under challenging operating conditions.Q: What are the benefits of the anti-corrosive paint and superior shaft materials?

A: Anti-corrosive paint and EN8/SS304 shaft materials protect the pump against chemical attack and wear, extending its operational life and reliability, especially when processing corrosive or abrasive western chemicals and viscous fluids.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+