Industrial CANDommercial Pressure Boosting System

Product Details:

- Theory Centrifugal

- Flow Rate Up to 240 m/h

- Material Cast Iron/SS304/SS316

- Structure Multistage Pump System

- Suction Type Single or Double Suction

- Volute Type Single or Double Volute

- Nozzle Location Side or Top

- Click to view more

Industrial CANDommercial Pressure Boosting System Price And Quantity

- 1 Piece

- Less than 70 dB

- 2 to 10 stages

- Manual/Auto

- Mechanical seal

- Digital/LED indicators

- IP54/IP55

- Base-mounted/Skid-mounted

- Air-cooled

- Automatic with pressure sensor and VFD

- IE2/IE3

Industrial CANDommercial Pressure Boosting System Product Specifications

- 2900/1450 rpm

- Electric

- DN32 - DN200

- Multistage Pump System

- Horizontal or Vertical

- Up to 240 m/h

- Up to 16 bar

- Side or Top

- Max 90C

- Single or Double Suction

- Centrifugal

- Not Applicable (Electric powered)

- Industrial water supply, Commercial buildings, Pressure boosting

- Single or Double Volute

- Cast Iron/SS304/SS316

- Less than 70 dB

- 2 to 10 stages

- Manual/Auto

- Mechanical seal

- Digital/LED indicators

- IP54/IP55

- Base-mounted/Skid-mounted

- Air-cooled

- Automatic with pressure sensor and VFD

- IE2/IE3

Industrial CANDommercial Pressure Boosting System Trade Information

- 1 Piece Per Week

- 20 Week

Product Description

Industrial & Commercial Pressure Boosting System:

Operating Conditions:

Flow range: Up to 457 m3/h

Pressure range: 0.7 to 26.4 kgf/cm2 (10 to 375 psi)

Ambient temperature: 0oC to +45oC

Water pH: 6.5 - 8

Applications:

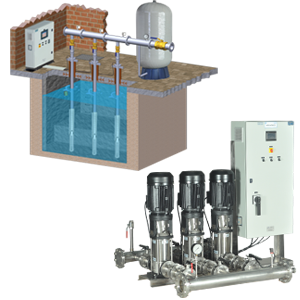

Lubi Subpack 1000 booster sets are designed for the transfer and pressure boosting of clean water for community water supply, apartment complex, hotels, hospitals, industries, commercial buildings, schools, bungalows et

Features:

Since submersible pumps are used on the Subpack pressure boosting system there is no priming requirement or requirement of costly mechanical seals for the pumps. The entire pressure booster system reliability is increased against a similar system of surface mount pumps due to this feature. There is no problem associated with foot valve leakage and mechanical seal leakage and system failure and damage to the pumps due to dry running is eliminated.

All pumps are of stainless steel 304 construction which has the following advantages. Operating energy costs are very low due to state-of-theart hydraulic design and usage of stainless steel 304 sheet metal which offers a very low coefficient of friction. Stainless Steel 304 offers wear and corrosion resistance. This also provides a hygienic water supply system for human consumption and also offers a very long life for the pumps. The motors used with the pumps can also be stainless steel 304 at additional cost.

Since all the pumps are installed in the water tank this system saves floor space which in turn is beneficial to the customer especially in metro cities where floor space costs are very high. Since all pumps are operating inside the water tank there is no noise or vibration of the pumps and hence offers a quieter installation. The Subpack system is designed so that any single pump can be removed with ease and serviced while the system operation is not affected while the pump is being serviced. This offers a high degree of system uptime to customers.

Advanced Control & Efficiency

Equipped with a digital control panel, the system uses a pressure sensor and variable frequency drive (VFD) for automatic or manual operation, maintaining stable water pressure and optimizing energy consumption. The motor efficiency levels (IE2/IE3) ensure reduced operational costs and eco-friendly performance.

Robust Design for Versatile Applications

Available in 2 to 10 pump stages, with single or double suction and volute types, the system can handle a variety of operational demands. Its air-cooled, noise-reduced operation (less than 70 dB) makes it suitable for installation in sensitive environments. Base-mounted or skid-mounted setups accommodate different installation needs.

Reliable and Safe Operation

Protected to IP54/IP55 standards, the booster system is designed for long-lasting performance in harsh industrial and commercial settings. Mechanical seals and quality construction materials (Cast Iron, SS304, SS316) resist wear and corrosion, while digital or LED indicators offer real-time monitoring for easier maintenance and operation.

FAQs of Industrial CANDommercial Pressure Boosting System:

Q: How does the automatic pressure boosting system operate?

A: The system uses a digital control panel with a pressure sensor and VFD to regulate water pressure automatically. It adjusts the pumps speed based on demand, ensuring a constant flow and pressure, with options to switch between manual and auto modes as required.Q: What are the main benefits of using this pressure boosting system in industrial or commercial buildings?

A: This system offers reliable water pressure, energy efficiency due to high-performance motors and VFD, low noise operation, and robust protection against environmental factors. These features combine to minimize downtime and maintenance costs, enhancing operational efficiency.Q: Where can this pressure boosting system be installed?

A: The system is designed for versatile installation and can be base-mounted or skid-mounted, fitting easily in plant rooms, basements, or on service platforms within commercial complexes and industrial facilities.Q: When should I consider using a multistage pressure boosting system?

A: When your application requires high water pressure and flowsuch as in high-rise buildings, process industries, or large-scale commercial water supplya multistage system provides the necessary capacity and reliability.Q: What is the process for installing and commissioning the system?

A: Installation involves placing the system on a suitable base or skid, connecting inlet and outlet pipes (DN32 to DN200), and setting up the electric supply. After mechanical and electrical checks, the commissioning team tests automatic pressure controls and verifies operational parameters.Q: How can I monitor and maintain this booster system?

A: Routine monitoring is carried out using the digital display or LED indicators, which show system status and performance in real time. Regular inspection of seals, electrical components, and the cooling system helps ensure optimal performance and longevity.Q: What materials are used, and how do they benefit long-term operation?

A: Key wetted parts are constructed from Cast Iron, SS304, or SS316, providing excellent resistance to corrosion and mechanical wearideal for long-term use in diverse water quality conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+