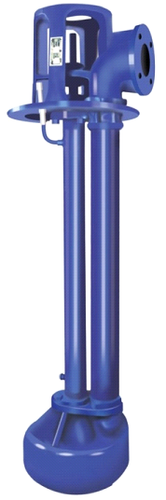

Submersible Wet Pit Pumps

Product Details:

- Impellars Type Closed / Semi-open

- Structure Single-stage or Multi-stage

- Motor Wet Type Submersible Motor

- Material Cast Iron / Stainless Steel

- Type Submersible Wet Pit Pump

- Style Vertical

- Power 5 HP to 200 HP

- Click to view more

X

Submersible Wet Pit Pumps Price And Quantity

- 1 Piece

Submersible Wet Pit Pumps Product Specifications

- Self-Priming

- Submersible Wet Pit Pump

- Up to 15 Bar

- 5 HP to 200 HP

- Vertical

- Single-stage or Multi-stage

- Electric

- Closed / Semi-open

- Mechanical Seal

- Cast Iron / Stainless Steel

- Single Suction

- Wet Type Submersible Motor

- IS 8034, IEC 60034

- Industrial Water Transfer, Sump Drainage, Effluent Treatment, Flood Control

Submersible Wet Pit Pumps Trade Information

- as per order Per Week

- as per order Week

Product Description

Submersible Wet Pit Pumps

Flow: Up to 7500 LPM

Head: Up to 55 Meters

Rating: 0.75kW to 40kW

Frequency: 50Hz

RPM:1450 /960

Supply: Three Phase 415 V

Motor: Vertical Flange mounted TEFC motor

RPM: 2 Pole, 4 Pole

Solid Passage: Up to 63 MM

Column Length: Up to 6 Meters

MOC: Various grades of Cast Iron & Various grades of SS

Special series of Pump are available for pumping hot temperature liquids.

Versatile Industrial Utility

Designed to meet demanding industrial requirements, these submersible wet pit pumps excel at transferring water, draining sumps, and managing effluent. Their robust construction, including cast iron or stainless steel options, helps tackle flood control and other critical water handling processes efficiently in diverse industrial environments.

Reliable Performance and Safety

With IP68 protection class and high-grade insulation, these pumps provide consistently safe operation even under challenging conditions. The water-cooled submersible motor and heavy-duty anti-friction ball bearings extend service life, while mechanical seals help prevent leakage, reducing downtime and maintenance demands.

FAQs of Submersible Wet Pit Pumps:

Q: How are Submersible Wet Pit Pumps installed in industrial settings?

A: These pumps are typically installed vertically in wet pits or sumps, fully submerged for efficient water transfer. Installation is straightforward due to their self-priming nature, and their single suction design allows for reliable operation in flooded environments.Q: What benefits do mechanical seals provide in these pumps?

A: Mechanical seals minimize leakage and ensure long-term reliability, particularly important in industrial water transfer and effluent treatment applications. This feature reduces maintenance needs and enhances operational safety.Q: When should I choose manual versus automatic flow control for these pumps?

A: Manual flow control is suitable for environments requiring hands-on adjustments, while automatic flow control, managed through a control panel, is ideal for continuous or remote operation, enhancing efficiency and reducing human intervention.Q: Where can submersible wet pit pumps be used most effectively?

A: They are ideal for industrial water transfer, sump drainage, effluent treatment, and flood control applications, commonly found in manufacturing plants, treatment facilities, and large storage reservoirs across India and abroad.Q: What process ensures motor durability in these submersible pumps?

A: Motor durability is achieved through water cooling and a wet type submersible design, along with F/H grade insulation and IP68 protection, safeguarding against moisture ingress and overheating during prolonged operation.Q: How does the pumps material affect performance and application?

A: Cast iron construction offers strength and corrosion resistance for standard environments, while stainless steel is preferred where chemical exposure or hygiene is critical, allowing for flexible application in various industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email