SPN Pumps

Product Details:

- Gear Type Helical

- Material Cast Iron

- Processing Type Standard

- Gear Tooth Profile Spur Gear

- Gearing Arrangement External

- Direction Clockwise

- Output Torque 6 Nm

- Click to view more

X

SPN Pumps Price And Quantity

- 1 , , Piece

SPN Pumps Product Specifications

- 85%

- 1440 RPM

- Standard

- 1440 RPM

- Helical

- Clockwise

- 220/440 V

- Spur Gear

- 2 HP

- Cast Iron

- 6 Nm

- External

SPN Pumps Trade Information

- Per Week

- Week

Product Description

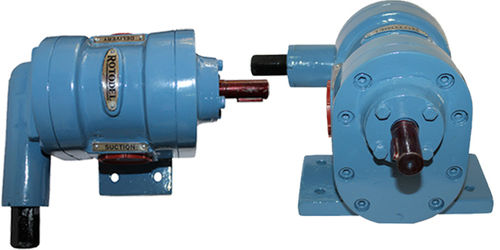

SPN Pumps is a global manufacturer of high-performance industrial pumps that are designed for various applications, including water treatment, mining, oil and gas, and other industrial processes. The company's products range from centrifugal and positive displacement pumps to slurry and submersible pumps, as well as custom-engineered solutions to meet specific customer requirements. With a strong focus on quality, innovation, and customer satisfaction, SPN Pumps has earned a reputation as a trusted supplier of reliable and efficient pumping solutions. The company operates from several locations worldwide, including North America, South America, Europe, Asia, and Africa, and serves customers in diverse industries across the globe.

Engineered for Resilient Industrial Performance

Designed for industrial oil transfer and hydraulic machinery, the SPN Foot Mounted Rotary Gear Pump thrives under tough environments. Its high-grade cast iron construction ensures durability, while the helical gear mechanism maximizes torque output at 6 Nm with a steady flow of 10 LPM even at high temperatures of up to 150C.

Reliable, Self-Lubricating System for Easy Maintenance

Featuring a self-lubricated rotary gear system, this pump minimizes the need for frequent maintenance, allowing for smooth operation in standard industrial processing applications. The external gear arrangement with a spur gear tooth profile delivers consistent and quiet performance.

FAQs of SPN Pumps:

Q: How does the SPN Foot Mounted Rotary Gear Pump benefit industrial oil transfer applications?

A: This pump provides a stable 10 LPM flow at pressures up to 10 Bar, making it ideal for precise, high-volume oil transfer in industrial and hydraulic machinery applications. Its high efficiency (85%) and robust build enhance reliability and reduce downtime.Q: What materials are used in the construction of this pump, and why?

A: The pump is crafted from durable cast iron, chosen for its excellent mechanical strength, resistance to wear under demanding industrial conditions, and longevity in continuous oil transfer processes.Q: When is maintenance required for the self-lubricated gear system?

A: Routine inspections are recommended, but the self-lubricated design minimizes frequent lubrication needs. Maintenance should generally be scheduled based on operational hours and application intensity, rather than constant upkeep.Q: Where is this rotary gear pump commonly used?

A: This pump is widely employed in Indian industrial settings such as factories handling oil transfer, hydraulic machinery, and standard processing plants, distributed through suppliers, exporters, and traders.Q: What is the installation process for this foot mounted pump?

A: Installation involves securely mounting the pump on a level surface using the designated foot mounts, connecting the 1-inch suction and discharge lines, ensuring voltage compatibility (220/440 V), and aligning the pump for clockwise rotation as specified.Q: How is the pumps gear arrangement advantageous for hydraulic machinery?

A: The external helical gearing and spur gear tooth profile provide steady torque (6 Nm) and consistent speed (1440 RPM), contributing to smoother operation, reduced vibration, and prolonged machinery life in hydraulic systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email