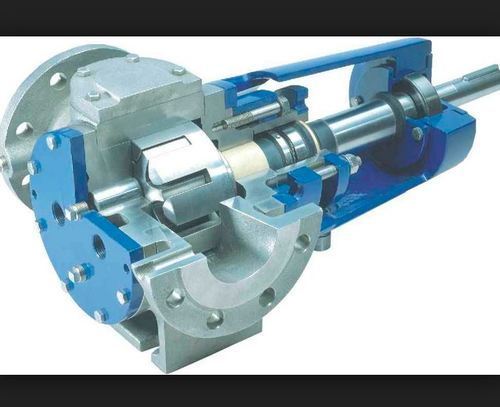

Rotary Gear Pump Type HGCX

Product Details:

- Gear Type Helical Gears

- Material Cast Iron / Stainless Steel / Bronze

- Processing Type Precision Machined

- Gear Tooth Profile Spur Type

- Gearing Arrangement External

- Direction Clockwise / Anticlockwise

- Output Torque Up to 50 Nm

- Click to view more

X

Rotary Gear Pump Type HGCX Price And Quantity

- 1 , , Piece

Rotary Gear Pump Type HGCX Product Specifications

- External

- 415V AC, 3 Phase

- Spur Type

- Up to 50 Nm

- Up to 95%

- Helical Gears

- 1440 RPM

- Precision Machined

- Clockwise / Anticlockwise

- 1440 RPM

- Up to 7.5 kW

- Cast Iron / Stainless Steel / Bronze

Rotary Gear Pump Type HGCX Trade Information

- as per order Per Week

- as per order Week

Product Description

Rotary Gear Pump Type HGCX Rotary Gear Pump in Mono-bloc version

To offer users of Rotodel Gear Pumps, top-notch range of products, we ensure only optimum grade supplies are utilized for their production.

Overview

Compact

Efficient

Leak Proof

Specifications:

Temperature - 120C Max.

Pressure - 7.0 Kg/cm2

Application - Lubrication/Transfer/Unloading

Motor - 4POLE/, RPM:1440

High-Efficiency Gear Technology

The HGCX rotary gear pump features precision-machined spur-type gears with an external gearing arrangement, enabling smooth fluid transfer with efficiencies of up to 95%. Its helical gear design minimizes pulsation and noise, making it ideal for continuous heavy-duty applications.

Versatile Fluid Handling

With compatibility for a variety of fluids, including oils, viscous liquids, fuels, and lubricants, this pump operates reliably up to 200C. The anti-corrosive coating and robust material options, such as cast iron, stainless steel, and bronze, ensure long-lasting performance in challenging environments.

Advanced Sealing and Mounting Options

Choose between mechanical seals or gland packing for tailored leak prevention and operational integrity. The foot mounting system offers easy installation, stability, and maintenance access, enhancing usability for distributors, exporters, suppliers, and traders throughout India.

FAQs of Rotary Gear Pump Type HGCX:

Q: How is the Rotary Gear Pump Type HGCX installed, and what mounting options are available?

A: The Type HGCX pump features foot mounting, allowing secure installation on a base or skid. This mounting type ensures stability and is suitable for industrial setups where vibration and movement must be minimized.Q: What types of fluids can be processed using the HGCX rotary gear pump?

A: This pump is designed to handle a wide variety of fluids, including oils, viscous liquids, fuels, and lubricants. Its materials and anti-corrosive coating enable it to reliably pump aggressive or high-temperature fluids up to 200C.Q: When should a mechanical seal versus gland packing be selected for sealing?

A: Mechanical seals provide superior leak prevention for hazardous, high-pressure, or high-temperature liquids, while gland packing is suitable for less aggressive fluids and more accessible maintenance. Selection depends on fluid type, operating conditions, and maintenance preferences.Q: Where can the HGCX rotary gear pump be sourced in India?

A: The pump is available through authorized distributors, exporters, suppliers, and traders across India, supporting a wide range of industrial sectors such as manufacturing, oil & gas, and processing plants.Q: What is the process for maintaining the HGCX pump, and does it require external lubrication?

A: The pump features a self-lubricating mechanism, minimizing maintenance needs. Routine inspection of seals, gland packing, and periodic cleaning of gear chambers will ensure reliable performance and extended lifespan.Q: What benefits does the anti-corrosive coating provide in industrial applications?

A: Anti-corrosive paint protects the pump body against harsh chemicals, moisture, and environmental wear, increasing operational reliability and reducing long-term maintenance costs.Q: How does the pumps efficiency and rated power impact operational costs?

A: With up to 95% efficiency and a rated power of up to 7.5 kW, the HGCX minimizes energy consumption while delivering high transfer rates, contributing to lower electricity bills and improved productivity in demanding industrial operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email