Nsd tupH Drives

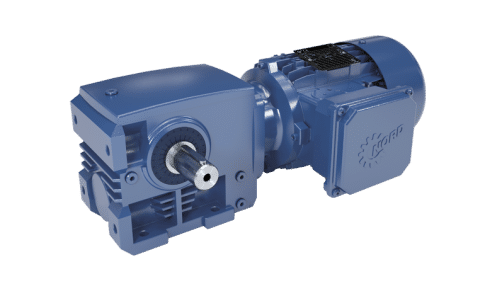

Product Details:

- Gear Type Worm / Helical

- Material Aluminum Alloy

- Processing Type NSD tupH Surface Treatment

- Gear Tooth Profile Helical

- Gearing Arrangement Right Angle / Inline

- Direction Reversible

- Output Torque Up to 800 Nm

- Click to view more

Nsd tupH Drives Price And Quantity

- 1 , , Piece

Nsd tupH Drives Product Specifications

- Up to 3000 rpm

- NSD tupH Surface Treatment

- Up to 800 Nm

- 0.18 kW to 7.5 kW

- Worm / Helical

- Reversible

- Aluminum Alloy

- Up to 96%

- Right Angle / Inline

- Helical

- Up to 400 rpm

- 220V / 380V / 415V

Nsd tupH Drives Trade Information

- as per order Per Week

- as per order Week

Product Description

Nsd tupH Drives:

nsd tupH for the food industry

Complies with FDA Title 21 CFR 175.300

Extensive tests have been performed with a wide range of cleaning agents

Advantages of nsd tupH

Corrosion-resistant and prevents contact corrosion

Easy to clean surfaces

Resistant to acids and alkalis (entire PH range)

No penetration of corrosion, even if damaged

No flaking

Cost effective alternative to stainless steel

Lighter than stainless steel

nsd tupH for extreme operatingand ambient conditions

Chemical cleaning (washdown entire PH range)

High ambient humidity

Offshore and coastal areas

Food and beverage industry

Car wash equipment

Dairies

Pharmaceutical industry

Water and sewage plants

nsd tupH Sealed Surface Conversion System

Surface treatment

No detachment possible

Corrosion-resistant - just like stainless steel

No flaking

No corrosion penetration

Complies with FDA Title 21 CFR 175.300

Products treated with NSD Tuph areideal for extreme ambient conditions and hygienerequirements.

Products available with nsd tupH

Nord SMI Series Worm Gear Units

Nordbloc Helical Inline Geared Motors

Nord Bevel Geared Motors

Nord Smooth Surface Motors

Nord Decentral Drive Solutions.

Superior Corrosion Resistance for Hygiene-Critical Applications

NSD tupH Drives are equipped with a non-painted, encapsulated aluminum casing treated with NSD tupH surface technology. This combination ensures exceptional resistance to chemicals and moisture, making them perfectly suited for the food, beverage, packaging, and marine industries. Their high protection rating (IP65/IP66) safeguards against dust and water ingress, supporting both operational safety and hygiene standards.

Versatile Mounting and Low-Maintenance Engineering

With flexible mounting choices flange, foot, or face NSD tupH Drives adapt seamlessly to varied installation layouts. Their life-time lubrication with synthetic oil and high-performance bearings guarantee prolonged, maintenance-free service. Designed for convenience, these gear units minimize downtime and optimize productivity in demanding environments.

FAQs of Nsd tupH Drives:

Q: How does the NSD tupH drive ensure long-term reliability in corrosive environments?

A: NSD tupH Drives feature a non-painted, encapsulated aluminum casing with advanced NSD tupH surface treatment, providing high corrosion resistance and durability. This design, along with their IP65/IP66 protection rating, ensures optimal performance in wet, chemical-intensive settings such as food and marine applications.Q: What application areas are these drives recommended for?

A: These drives are suitable for the food industry, beverage production, packaging sectors, and marine environments, where hygiene, chemical resistance, and low noise operation are critical. Their robust build and high performance support a variety of demanding workflows.Q: When should I choose flange, foot, or face mounting for my NSD tupH Drive installation?

A: The choice of mounting depends on your systems layout and available space. Flange mounting suits vertical installations, foot mounting is ideal for horizontal setups, and face mounting allows adaptation to complex machinery designs. Selecting the right mounting facilitates seamless integration into your equipment.Q: Where can I source NSD tupH Drives in India?

A: NSD tupH Drives are available through authorized distributors, suppliers, exporters, and traders across India. These partners provide expert guidance on product selection and support for installation in diverse industrial setups.Q: What process and maintenance requirements do NSD tupH Drives have?

A: Thanks to lifetime lubrication with synthetic oil and high-performance bearings, these drives require minimal maintenance. Their encapsulated casing and surface treatment further reduce cleaning frequency, allowing safe operation in hygiene-sensitive industries.Q: How are NSD tupH Drives used to benefit operational efficiency?

A: Delivering up to 800 Nm output torque, rated power from 0.18 kW to 7.5 kW, and efficiency as high as 96%, NSD tupH Drives maximize productivity while maintaining low noise levels. Their reversible direction capability and robust gearing arrangement also enhance process flexibility and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+