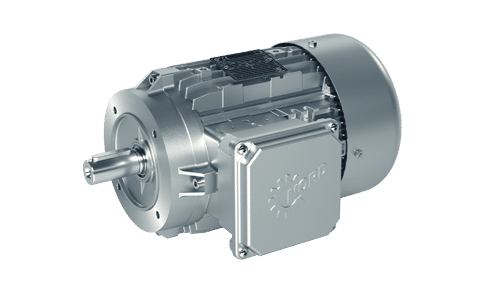

Bevel Helical Geared Motor - Bevel Helical Gear Box

Product Details:

- Gear Type Right Angle Bevel Helical

- Material Cast Iron / Steel

- Processing Type Forged / Precision Machined

- Gear Tooth Profile Helical & Bevel

- Gearing Arrangement Bevel Helical

- Direction Horizontal or Vertical

- Output Torque Up to 50000 Nm

- Click to view more

Bevel Helical Geared Motor - Bevel Helical Gear Box Price And Quantity

- 1 Piece

Bevel Helical Geared Motor - Bevel Helical Gear Box Product Specifications

- 5 400 rpm

- Helical & Bevel

- Up to 96%

- Up to 50000 Nm

- Up to 1800 rpm

- Horizontal or Vertical

- Bevel Helical

- Up to 200 kW

- Forged / Precision Machined

- Cast Iron / Steel

- 220-415V

- Right Angle Bevel Helical

Bevel Helical Geared Motor - Bevel Helical Gear Box Trade Information

- as per order Per Week

- as per order Week

Product Description

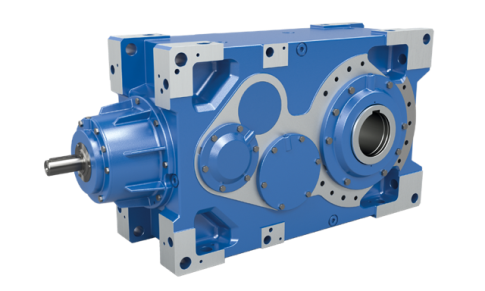

MAXXDRIVE Helical gear units - Industrial gear units

Performance: 1.5 - 4,000 kW

Torque range: 15,000 - 250,000 Nm

| Sizes: | 11 |

| Mounting position: | M1 - M6 |

| Ratio: | 5.6: 1 - 30 000: 1 |

Versions:

Various output shaft bearings for optimum adaptation to the application

Many output flange options

Various methods of attaching or mounting the motor

Effective cooling with air or water

Supply of ready to install complete systems with coupling, brakes, monitoring, etc. is possible

Characteristics & Advantages:

Optimum sealing protects against lubricant leakage

Low noise operation reduces noise nuisance

High torque capacity

Increased lubricant life minimises maintenance costs

Symmetrical design

Standard B14 flange on the output side as standard

6 possible installation positions suitable for a wide range of applications

Mirror-image and inclined installation possible

Same housing size and installation dimensions for all gear ratios (2- and 3- stage)

Input and output shafts can be adapted to customers' dimensions

Great reliability

Long service life

High precision

Applications:

Agitators

Lifting gear

Extruders

Mixers

Mills

Drums

Crushers

Lifts

And many more

Highly Durable & Versatile Construction

Crafted from cast iron or steel and processed through forging and precision machining, the Bevel Helical Geared Motor offers exceptional strength and reliability. Its housing is treated with a corrosion-resistant paint, ensuring lasting performance in harsh environments. The gearbox supports both horizontal and vertical orientations, adapting seamlessly to your industrial setup.

Advanced Gearing Arrangement & Efficiency

Utilizing a combination of helical and bevel gears, this motor delivers smooth power transmission and minimizes energy losses. With an impressive efficiency rate of up to 96%, it is suitable for applications where energy savings and quiet operation are paramount. Multi-stage variants can achieve high reduction ratios for diverse industrial demands.

Flexible Mounting & Input Options

Choose from foot, flange, or shaft mounting to fit new or retrofit installations. The gear motor accepts electric motors, IEC adaptors, or free input shafts, giving it compatibility with a wide variety of machinery. This flexibility enhances its applicability across sectors like manufacturing, material handling, and processing industries.

FAQs of Bevel Helical Geared Motor - Bevel Helical Gear Box:

Q: How does the Bevel Helical Geared Motor improve operational efficiency?

A: By employing a precision-engineered combination of helical and bevel gears, this geared motor minimizes energy losses, ensuring efficiency levels up to 96%. Its design supports smooth and quiet power transmission, which can significantly enhance overall system performance.Q: What mounting and input options are available for this gearbox?

A: The gear motor offers foot, flange, and shaft mounting options, enabling it to fit a variety of machinery configurations. Input methods include a standard electric motor, IEC adaptor, or free input shaft for maximum flexibility in integration.Q: When should oil splash or forced lubrication be used?

A: Oil splash lubrication is suitable for standard applications with moderate loads and speeds, while forced lubrication is recommended for high-load or high-speed operations. This ensures optimal gear performance and longevity under varied operating conditions.Q: Where can the Bevel Helical Geared Motor be installed within industrial setups?

A: Thanks to its enclosure protection ratings (IP55/IP65) and corrosion-resistant paint, this geared motor can be installed in challenging environments where dust, water, or chemical exposure is likely. Its ruggedness makes it ideal for both indoor and outdoor industrial settings across India.Q: What process is used to ensure gear quality and strength?

A: Gears are produced using forging and precision machining processes. This guarantees strong, uniform components with accurate tooth profiles, which enhances both durability and operational smoothness.Q: How does the service factor impact usage?

A: The service factor of 1.5 to 2.0 indicates the gearbox is designed to handle loads above its nominal rating, allowing for additional safety and longer service life even in demanding, continuous-duty applications.Q: What benefits does S1 continuous duty cycle operation offer?

A: S1 continuous duty cycle means the geared motor can run non-stop at rated power without overheating, making it ideal for critical industrial processes that require uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+