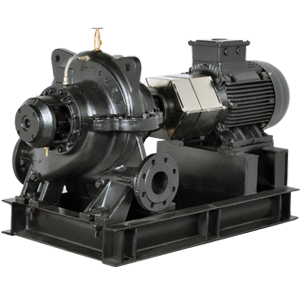

Horizontal Split Case Pumps

Product Details:

- Material Cast Iron / Ductile Iron / Bronze / Stainless Steel

- Processing Type Casting

- Gear Tooth Profile Not Applicable (Centrifugal Impeller)

- Direction Clockwise / Anti-clockwise

- Rated Power Up to 1500 kW

- Input Speed 980 to 2900 RPM

- Output Speed Same as Pump Speed

- Click to view more

Horizontal Split Case Pumps Price And Quantity

- 1 Piece

- -10C to 120C

- 80 mm to 800 mm

- Water Supply, Irrigation, HVAC, Fire Fighting, Industrial

- Up to 200 m

- Up to 10000 m/hr

- Conforms to IS 9137, ISO 2548/5199

- Horizontal Split Case Centrifugal Pump

- Heavy Duty Antifriction Bearing

- Double Suction, Dynamically Balanced

- Gland Packing / Mechanical Seal

- Axially Split Double Suction

- Horizontal Foot Mounted

- Up to 25 bar

Horizontal Split Case Pumps Product Specifications

- Up to 90%

- Same as Pump Speed

- 380V / 415V / 440V, 3 Phase

- Cast Iron / Ductile Iron / Bronze / Stainless Steel

- Not Applicable (Centrifugal Impeller)

- Clockwise / Anti-clockwise

- 980 to 2900 RPM

- Casting

- Up to 1500 kW

- -10C to 120C

- 80 mm to 800 mm

- Water Supply, Irrigation, HVAC, Fire Fighting, Industrial

- Up to 200 m

- Up to 10000 m/hr

- Conforms to IS 9137, ISO 2548/5199

- Horizontal Split Case Centrifugal Pump

- Heavy Duty Antifriction Bearing

- Double Suction, Dynamically Balanced

- Gland Packing / Mechanical Seal

- Axially Split Double Suction

- Horizontal Foot Mounted

- Up to 25 bar

Horizontal Split Case Pumps Trade Information

- as per order Per Week

- as per order Week

Product Description

Lubi Horizontal Split Case Pumps

Capacity: upto 2700 M^3/Hr.

Head: Upto 160 Meters

The Lubi horizontal split case pump, type LHC is available in two main designs:

Single-stage

Two-stage

Applications:

Water Supply. Pressure boosting for high rise buildings, hotels, industry etc.

Industrial washing & cleaning systems. Fire Protection systems.

Cooling & Air Conditioning systems. Boiler feed and condensate transfer system.

Irrigation systems for fields including sprinkler & drip irrigation systems.

Features & benefits:

Following are the main features and benefits offered by the LHC pumps.

The pumps are non self-priming horizontal split case pumps with radial suction port and radial discharge port.

Standard flanges for suction and discharge ports will be PN 16 as per DIN standard EN 1092-2 and PN 25 as per DIN standard EN 1092-2. ANSI 125 and ANSI 250 as per ASME B16.1 are available on request.

These pumps are long coupled pumps with TEFC squirrel cage induction motor with main dimensions complying to IEC standards and mounting designation B3 (IM 1001).

These pumps are available with gland packing as well as mechanical shaft seal.

These pumps can be supplied as a complete unit with motor, coupling, coupling guard and fabricated steel base frame.

These pumps are available with IE2 motors.

The split case construction enables removal and dismantling of the internal pump parts e.g. bearings, wear rings, shaft seal and impeller without disturbing the motor & pipe work.

Precision Pumping with Proven Engineering

These horizontal split case centrifugal pumps are engineered with axially split, double suction design and heavy-duty antifriction bearings, ensuring consistent and reliable operation. Their dynamically balanced impellers minimize vibration and optimize energy efficiency, reaching up to 90%. Supported by international standards and adaptable mounting, they suit diverse duties from municipal water transport to industrial cooling systems.

Versatile Applications for Multiple Industries

With discharge sizes ranging from 80 mm to 800 mm and wide tolerance for flow and pressure, these pumps demonstrate exceptional adaptability. Whether your requirement is for irrigation in agriculture, fire safety in buildings, centralized HVAC systems, or industrial processing, their robust build and safeguard mechanisms ensure uninterrupted fluid delivery even in demanding environments.

FAQs of Horizontal Split Case Pumps:

Q: How do horizontal split case centrifugal pumps improve operational reliability?

A: Horizontal split case centrifugal pumps feature axially split double suction casing and heavy-duty antifriction bearings, which reduce maintenance frequency and ensure stable, vibration-free operation. The dynamically balanced impeller also prolongs pump life and reduces downtime in critical fluid transfer systems.Q: What applications are suitable for these horizontal split case pumps?

A: These pumps are ideal for water supply, irrigation, HVAC, fire fighting, and various industrial processes. Their broad flow and pressure capacities make them effective in municipal, commercial, and industrial settings that require reliable and efficient fluid transport.Q: When should I opt for gland packing versus mechanical seals in these pumps?

A: Gland packing is suitable for lower pressure or non-hazardous fluid environments, while mechanical seals are preferable for higher pressure, temperature, or when leakage control is critical. Selection depends on specific process requirements and safety considerations.Q: Where are these pumps typically installed and operated?

A: Horizontal split case pumps are usually installed in pump rooms, mechanical spaces, water treatment facilities, industrial plants, and agricultural irrigation setups. Their horizontal foot mounting design provides stability and easy access for maintenance.Q: What materials are available for the construction of these pumps?

A: Depending on application needs, pumps can be manufactured from cast iron, ductile iron, bronze, or stainless steel, each material offering different levels of corrosion resistance, durability, and suitability for various fluids.Q: How does the pumps double suction impeller enhance its performance?

A: The double suction impeller design allows fluid to enter from both sides, reducing axial thrust and increasing efficiency. This structure is especially beneficial for high-flow, low-NPSH applications, improving energy effectiveness and service longevity.Q: What are the benefits of using pumps conforming to IS 9137 and ISO 2548/5199 standards?

A: Compliance with IS 9137 and ISO 2548/5199 ensures that the pumps meet stringent safety, reliability, and performance standards. This guarantees superior build quality, operational efficiency, and consistent results, essential for dependable fluid handling in critical systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+